Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

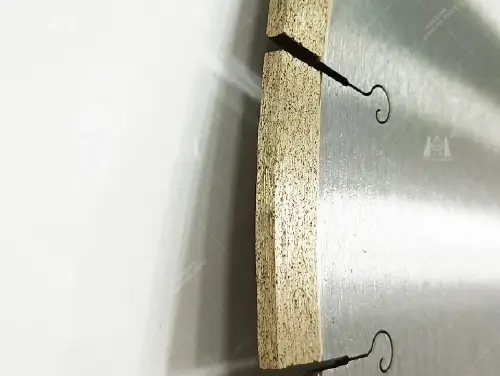

Sintered Diamond Saw Blade for Ceramic & Porcelain

105-350mm

Compatible Materials & Products

Chip‑free wet cutting for dense porcelain and ceramic tiles

Porcelain Tile > Straight Cutting

Sintered continuous‑rim diamond blade for porcelain tile wet cutting; fine diamond grit, steady RPM and controlled feed maintain kerf stability, reduce micro‑chipping and edge spall. Use adequate water coolant to dissipate heat. Achieve chip‑free straight cuts, smooth edges, fast feed rate and long blade life on dense porcelain.

Ceramic Tile > Clean Edge Cutting

For ceramic tile edge finishing and glaze compatibility, a continuous‑rim diamond blade with ceramic‑tuned bond and constant water feed grinds the glaze instead of fracturing it. Keep moderate feed and RPM window to avoid thermal shock. Delivers clean, sharp edges with minimal rework, reduced polishing time and consistent finish quality.

Glazed Tile > Finish Cuts

On glazed tiles, fine diamond grit plus continuous‑rim geometry and constant water cooling stabilize the kerf and prevent micro‑chipping near the finish. Use light passes close to the cut line and avoid dwell to protect the glaze. Results: flawless finish, lower Ra roughness, improved aesthetics and less material waste in finish cuts.

Vitrified Tile > Long Kerf Control

For dense, abrasive vitrified tiles, matched sintered bond hardness, rigid core, wet cutting and correct RPM/linear speed keep the kerf straight over long cuts and resist blade glazing. Maintain coolant flow to control heat. Benefit: stable kerf, high precision on large‑format tiles, consistent cutting speed and service life.

Mosaic Tile > Fine Detailing

Thin mosaic tiles need low‑pressure precision; a continuous‑rim fine‑grit blade with short passes, accurate RPM and water cooling prevents tile fracture during shaping. Use gentle feed for profiling small pieces. Achieve precise detailing, clean profiles and reliable chip‑free results on delicate mosaic patterns.

Specs and options

Specifications customizable upon request.

| Diameter | Segment Width | Segment Height | Arbor | |

|---|---|---|---|---|

| Inches | mm | mm | mm | mm |

| 4.13" | 105 | 1.6 | 8 | 20 / 22.23 |

| 4.3" | 110 | 1.4 | 5/8 | 20 / 22.23 |

| 4.5" | 115 | 1.6 | 8 | 22.23 |

| 5" | 125 | 1.4 | 8 | 22.23 |

| 6" | 150 | 1.6 | 8 | 22.23 |

| 7" | 180 | 1.6 | 8 | 22.23 |

| 8" | 200 | 1.6 | 10 | 22.23 |

| 9" | 230 | 2 | 10 | 22.23 |

| 12" | 300 | 2.2 | 10 | 50 / 25.4 |

| 14" | 350 | 2.6 | 10 | 50 / 25.4 |

Cut Faster, Stay Smooth. Built for Porcelain.

Continuous‑rim wet blade for porcelain/ceramic; fine grit edge.

Smooth Kerf Control

Rigid, tensioned steel core + continuous‑rim keep the kerf straight, reducing wobble/deflection on large‑format porcelain/vitrified tiles.

Clean Finish on Glaze

Fine diamond grit and a continuous rim grind the glaze with low impact; constant wet feed clears swarf for a chip‑free, premium finish.

Lower Ra Roughness

Wet feed and optimized rim profile lower Ra roughness, leaving smoother edges/surfaces and faster finishing.

FAQs

Common Questions About Sintered Diamond Saw Blade for Ceramic

Can a continuous-rim diamond blade cut porcelain tile?

Porcelain's dense, brittle structure makes it prone to chipping with the wrong blade.

Yes, a continuous-rim diamond blade is the ideal choice. Its solid, unbroken edge provides the smoothest cut, minimizing stress on the material. For best results, use a sintered blade with wet cooling and operate within the recommended RPM window to prevent heat buildup and ensure a clean edge.

Before ordering, verify that the blade complies with safety standards like EN 13236 and select the correct diameter and arbor size for your tile saw.

How to finish ceramic tile glaze without chipping?

Achieving a perfect finish on glazed ceramic requires preventing micro-fractures in the top layer.

Follow these steps for a clean finish:

- Use a continuous-rim blade with fine diamond grit.

- Ensure a constant flow of water for cooling and debris removal.

- Maintain a steady, moderate feed rate; do not force the blade through the tile.

This approach significantly reduces the risk of chipping, delivering a professional-grade edge that often requires no secondary polishing.

How to choose a blade for hard vitrified tiles?

Vitrified tiles are extremely hard and require a blade with a specialized bond to withstand high abrasion.

Select a sintered continuous-rim blade specifically designed for hard ceramics. The key is the bond hardness; it must be formulated to wear at a controlled rate to expose new diamonds. Also, ensure your saw can operate at the blade's recommended RPM/linear speed range to optimize performance and prevent overheating.

A correctly matched blade ensures faster cutting, longer tool life, and prevents blade glazing or premature wear.

Does a continuous-rim reduce chipping on glazed tiles?

Chipping on glazed tiles occurs when the cutting action creates excessive impact force on the brittle surface.

Yes, it is the most effective design for this purpose. Unlike segmented or turbo blades, the continuous-rim provides a smooth, uninterrupted cutting surface. This minimizes vibration and impact, allowing the fine diamond particles to grind through the glaze rather than chipping it.

This mechanism results in a significantly cleaner cut, preserving the aesthetic quality of the tile and reducing material waste.

What specs to confirm before buying a ceramic saw blade?

Ordering the wrong blade can lead to poor performance, tool damage, or safety risks.

Before purchasing, confirm the following specifications:

- Diameter & Arbor Hole: Must match your tile saw's capacity and spindle size.

- Bond Type: Ensure it is formulated for hard porcelain/ceramic.

- Cutting Method: Confirm it is designed for wet cutting.

- Compliance: Check for certifications like EN 13236.

Confirming these details ensures you receive a blade that is safe, efficient, and perfectly suited to your application.

Certifications & Standards

Continuous‑rim wet blade for porcelain/ceramic; fine grit edge.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Get Chip‑free Cuts on Porcelain & Ceramic Tiles

Request a quote and technical matching for diameter, arbor, and RPM window.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Saw Blade Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский