Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

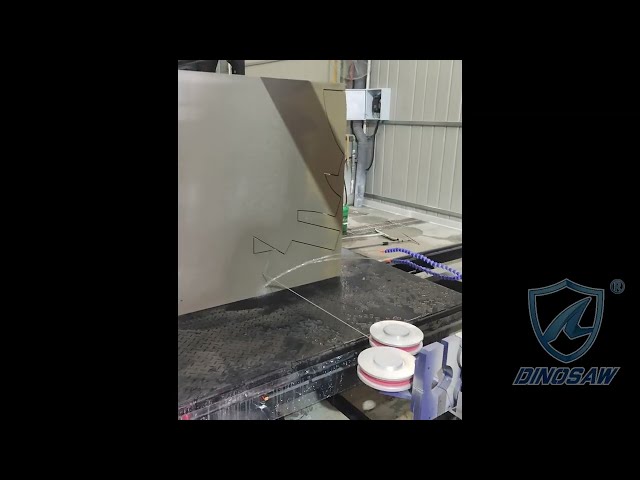

Foam ceramic letter cutting case study using CNC wire saw cutting, focusing on shape accuracy, edge cleanliness, and suitability for signage and display element production.

▶

▶Case Snapshot

Material

Foam ceramic

Processing Method

CNC wire saw contour cutting

Typical Application

Foam ceramic letters and text elements for signage and visual display

Applicable Markets

Architectural signage, commercial display fabrication, decorative building elements

Processing Focus

Accurate contour cutting of letters and characters with clean edges in foam ceramic

Associated Product

DINOSAW CNC wire saw foamed ceramic cutting machine

Foam Ceramic Letter Cutting for Signage and Display Applications

Foam ceramic letters are commonly used in architectural signage, branding elements, and decorative displays where lightweight construction and clean visual definition are required.

These letters are often installed on façades, interior feature walls, exhibition structures, or promotional installations.

Production typically starts from rectangular foam ceramic blocks or panels that are cut into individual letters or characters.

Because the final product is viewed from close range, the cut shape itself defines the visual quality, making contour accuracy and edge condition central to the process.

Practical Challenges in Cutting Foam Ceramic Letters

Cutting letters from foam ceramic introduces challenges beyond simple straight or block cutting.

Letter shapes involve frequent direction changes, internal corners, and narrow sections.

The material is lightweight but brittle, making it sensitive to vibration or uneven force.

Edges can chip easily if the cutting path is not smooth.

Consistency becomes critical when multiple letters are arranged together as words or signage elements.

Workshop Insights from Foam Ceramic Letter Cutting

What makes foam ceramic letter cutting difficult in practice?

From the workshop’s point of view, the challenge is not removing material, but controlling the shape.

Letters have tight corners and thin strokes, and foam ceramic does not forgive sudden movement.

If the cut hesitates or shifts, the defect is immediately visible in the final letter.

Why is wire saw cutting suitable for foam ceramic letters and text shapes?

Wire saw cutting allows the path to follow letter outlines smoothly.

The wire moves continuously through curves and corners without concentrating force at a single point.

This helps preserve edge integrity, especially in narrow or detailed parts of the letter.

What do operators focus on most during the letter cutting process?

Operators focus on keeping the block stable and watching how the wire behaves through sharp turns.

They pay attention to areas where strokes narrow or intersect, since those sections are most prone to damage.

Maintaining steady movement is more important than cutting speed in this type of work.

How is acceptable quality judged on the workshop floor?

Quality is judged visually and practically.

Edges should look clean, letter shapes should match the intended outline, and the piece should be ready for installation or finishing without repair.

If letters can be assembled into words without visible inconsistency, the cut is considered acceptable.

How the Foam Ceramic Letter Cutting Process Was Handled

Foam ceramic blocks were secured to prevent movement during contour cutting.

Predefined cutting paths guided the wire saw along letter outlines and internal shapes.

The cutting process emphasized smooth, continuous motion through curves and corners.

After cutting, letters were visually inspected for shape accuracy and edge condition before proceeding to finishing or installation.

Observed Results in Foam Ceramic Letter Processing

Finished letters showed clear outlines and consistent shapes.

Edges remained clean and intact, supporting direct use in signage and display applications.

Multiple letters cut from the same setup aligned well when assembled.

The process fit naturally into small-batch or customized production workflows.

Who This Case Is Relevant For

If you are producing foam ceramic letters or text elements for signage or display use,

if your applications involve detailed shapes rather than simple blocks,

if edge quality and visual consistency matter in final presentation,

this case reflects a practical processing scenario commonly seen in decorative foam ceramic fabrication.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский