Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

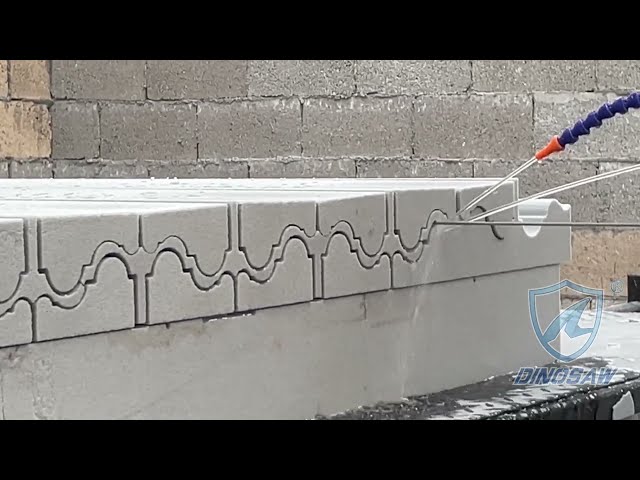

Foam ceramic window trim profile cutting case study using CNC wire saw, showing how architectural mouldings and decorative window surrounds are shaped with clean edges and consistent profiles.

▶

▶Case Snapshot

Material

Foam ceramic

Processing Method

CNC wire saw profile and contour cutting

Typical Application

Architectural window trims, mouldings, and decorative surrounds

Applicable Markets

Architectural decoration, prefabricated façade systems, building component fabrication

Processing Focus

Accurate profile cutting of repetitive window trim shapes with clean edges and consistent geometry

Associated Product

CNC wire saw machine for Foam Ceramic cutting

Foam Ceramic Window Trim Production in Architectural Projects

Foam ceramic window trims are commonly used as decorative and functional elements around windows, openings, and façade details.

They are often designed as repeating profiles that run continuously along building elevations, requiring consistent geometry from piece to piece.

Unlike flat panels, window trims are defined by their cross-sectional profile.

The accuracy of the profile directly affects how well pieces align during installation and how clean the finished façade appears.

As a result, profile cutting becomes a critical stage in the production of foam ceramic window surrounds.

Practical Challenges in Cutting Foam Ceramic Window Trim Profiles

Producing window trims from foam ceramic introduces several practical challenges in workshop conditions.

The material is lightweight and easy to cut, but it reacts quickly to unstable movement.

Profiles often include curves, steps, and recessed details that must remain sharp and consistent.

Small defects along the edge become very noticeable once trims are installed in long, continuous runs.

Consistency across batches is essential, especially when trims are produced over multiple days or production cycles.

Workshop Insights from Foam Ceramic Window Trim Cutting

What makes foam ceramic window trim cutting challenging in daily production?

In practice, the difficulty is not the hardness of the material, but the shape itself.

Window trims repeat the same profile over and over, so any small deviation stands out once pieces are lined up on the wall.

Foam ceramic cuts easily, but if the motion is uneven, the profile loses its definition very quickly.

Why is wire saw cutting suitable for window trim profiles?

Wire saw cutting allows the profile to be followed smoothly without stressing the material.

For trims with curved and stepped sections, the wire transitions naturally through the shape.

This helps keep the edges clean and the profile consistent, which is exactly what installers care about on site.

What do operators pay most attention to during the cutting process?

Operators focus first on how the block is supported, because movement during cutting shows up immediately in the profile.

They also watch the wire closely as it moves through corners and recesses, where defects are most likely to appear.

The goal is a steady, predictable cut rather than a fast one.

How is acceptable quality judged on the workshop floor?

Quality is judged by how the trim pieces fit together visually.

If multiple pieces can be placed end to end and the profile lines up without gaps or uneven transitions, the cut is considered good.

When trims can go straight to installation or coating without touch-up, the result meets workshop expectations.

How the Foam Ceramic Window Trim Cutting Process Was Handled

Foam ceramic blocks were positioned and secured to ensure stable cutting along the profile.

Predefined profile paths guided the wire saw through curved and stepped sections in a continuous motion.

The cutting process emphasized smooth progression and shape consistency rather than aggressive material removal.

After cutting, trims were visually checked for profile accuracy before being moved to finishing or installation stages.

Observed Results in Foam Ceramic Window Trim Processing

Finished window trims showed clear, well-defined profiles with clean edges.

Pieces produced in the same run aligned consistently when placed together.

Surface condition supported downstream coating or finishing without corrective reshaping.

The cutting process integrated smoothly into routine architectural component production.

Who This Case Is Relevant For

If you are producing foam ceramic window trims or architectural mouldings,

if your projects require repeated profiles with consistent geometry,

if installation quality depends on clean edges and accurate profile definition,

this case reflects a practical processing scenario commonly seen in architectural foam ceramic fabrication.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский