Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

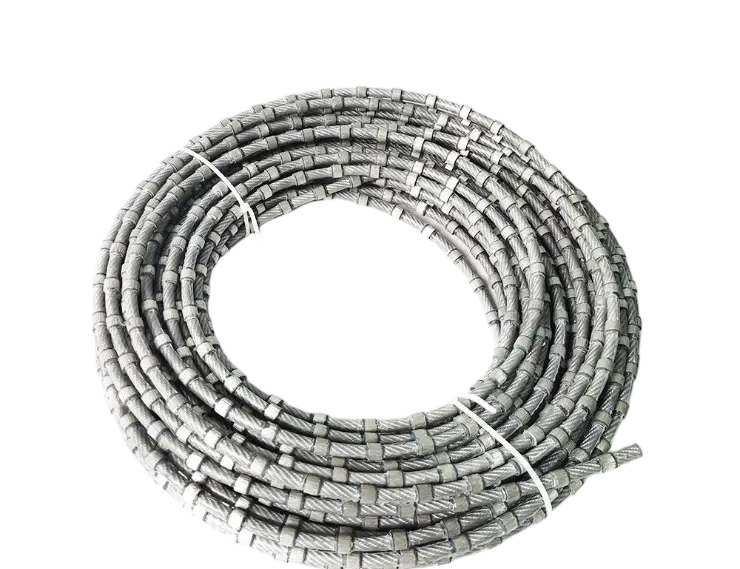

Don't guess. Our guide helps you select the right diamond wire saw based on material, cut type, and budget. Use our If-Then guide for a quick decision.

TL;DR: The Right Wire for the Right Job

- Selection depends diamond wire saw on four key factors: the material's hardness, the required cut type (block vs. slab), machine power, and desired finish.

- Use our "If-Then" decision tree below for a quick recommendation based on your specific scenario.

- Considering Total Cost of Ownership (TCO) over initial price leads to better long-term ROI.

Why Your Choice of Wire Defines Your Project's Success

Your 30-Second Decision Guide for Concrete, Marble & Granite Cutting Wire

- If you are quarrying large blocks of hard granite and require maximum durability, then a sintered wire on a high-power (≥37kW) Quarry Wire Saw Machine is your best choice. (Risk: High abrasion requires durable beads; incorrect tension causes wire deviation).

- If you need to cut heavily reinforced concrete for demolition, then a brazed wire with a rubber connection is essential for its aggressive cut and ability to absorb shocks from hitting rebar. (Caution: Wet cutting is mandatory to control silica dust per OSHA standards).

- If your primary job is slicing high-value marble slabs with a perfect finish, then an electroplated wire is ideal for its precision and minimal chipping. (Risk: Material is fragile; incorrect speed causes chipping, a topic detailed in our Gangsaw vs Wire Saw comparison).

- If you need to perform complex, non-linear cuts on a CNC machine, then an electroplated wire provides the required accuracy and fine finish. (See our CNC diamond wire saw guide for more).

- If your project involves underwater cutting of steel piles or structures, then a brazed wire with robust rubber connections is necessary for safety and performance in subsea environments. (Caution: Always follow IMCA guidance for offshore operations).

- If you are on a tight budget and need a versatile, all-around solution for various materials, then a general-purpose brazed Diamond Wire Saw offers the best balance of cost and speed. (Risk: Lifespan is shorter than sintered wire on highly abrasive materials).

Decision Drivers: What Matters Most in Your Choice?

Sintered Wire (For Durability)

Brazed Wire (For Versatility)

Electroplated Wire (For Precision)

Beyond the Wire: Key Procurement Topics to Consider

- Total Cost of Ownership (TCO): Look beyond the initial price. Factor in wire lifespan (meters cut per wire), potential downtime, and maintenance costs. A cheaper wire that breaks often is more expensive in the long run.

- Spare Parts & Maintenance Window: Can the supplier provide spare parts like pulleys and connectors quickly? A reliable supply chain is critical to minimizing downtime.

- Operator Training & Warranty: Does the purchase include operator training? A solid warranty and accessible technical support are signs of a trustworthy partner.

- Certifications (CE, ISO): Certifications ensure the product meets international safety and quality standards, which is non-negotiable for professional use.

Our Recommendations by Scenario

For Quarries

For Fabrication Shops

For Demolition Contractors

Summary

Frequently Asked Questions (FAQs)

Is a more expensive wire always better?

- Context:An expensive sintered wire for granite will perform poorly on reinforced concrete compared to a purpose-built brazed wire. Focus on getting the right specification for the job to optimize performance.

How do I choose the right wire diameter?

- Context:Standard diameters are 8.0-11.5mm for block/concrete cutting. Diameters of 7.3mm or less are for multi-wire or CNC machines. Your machine is designed for a specific range.

Can I use a granite cutting wire on marble?

- Context:A hard-bond wire for granite may cut too slowly and aggressively on marble. For high-value marble where finish is key, an electroplated or soft-bond sintered wire is better for a cleaner cut.

What's the impact of machine power (kW) on wire selection?

- Context:A high-power machine (37kW+) can drive a hard-bond wire through tough granite. Using that same wire on a low-power machine (22kW) will cause slow cutting or stalling. Always match the wire's aggressiveness to the machine's capability.

Should I choose a wire based on cutting speed or lifespan?

- Context:A faster-cutting brazed wire might be better for a production line, while a longer-lasting sintered wire is preferable for a remote quarry. The best decision is based on cost per square meter.

What causes damage to a diamond wire during rebar cutting?

- Context:Proper tensioning prevents bowing, sufficient coolant prevents overheating, and a clear path prevents snags. Operator training on these three points is the best way to maximize wire lifespan during rebar cutting.

How many times can a diamond wire be repaired via wire splicing?

- Context:Each splice creates a potential weak point. For safety, especially in high-tension quarrying, it's best to retire the wire after several repairs and use professionally made joints.

Does water quality affect wire performance?

- Context:Using clean, pH-neutral water is recommended to prevent corrosion, especially if the wire's protective coating is damaged. In closed-loop systems, filtering slurry is crucial to prevent re-abrasion.

- Next Step:Incorporate water quality checks into your preventative maintenance schedule.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский