Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Understand cold cutting with no heat‑affected zone. Materials: stone, glass, metals, composites; pros/cons, abrasives, costs and ROI. Practical tips inside. Read the guide.

Looking for the Right Abrasive Water Jet Cutting Solution? Here's What You Need to Know

Choosing the wrong cutting equipment costs businesses thousands in lost productivity and material waste. If you're considering abrasive water jet cutting, you need answers to three critical questions:

Is abrasive water jet cutting right for your needs?

This technology excels when you need precision cutting, achieve 0.1mm accuracy, or process heat-sensitive materials without thermal distortion.

What's the real return on investment?

ROI varies significantly based on material type, thickness requirements, and system specifications. The key is matching your production needs to the right equipment capabilities.

Why does equipment selection matter? Wrong choices lead to:

- Higher operating costs from inefficient abrasive consumption

- Productivity bottlenecks from inadequate cutting speeds

- Quality issues from insufficient pressure systems

- Costly downtime from unreliable components

This guide provides practical information for informed purchasing decisions, covering abrasive selection, operating costs, system specifications, and supplier evaluation.

What you'll learn:

- True operating costs beyond initial purchase price

- Best abrasive types for your specific materials

- Key technical specifications impacting performance

- How to evaluate suppliers and avoid costly mistakes

Ready to make the right investment? Let's explore what makes abrasive water jet cutting the precision solution your competitors are using.

✅More info of Abrasive Water Jet

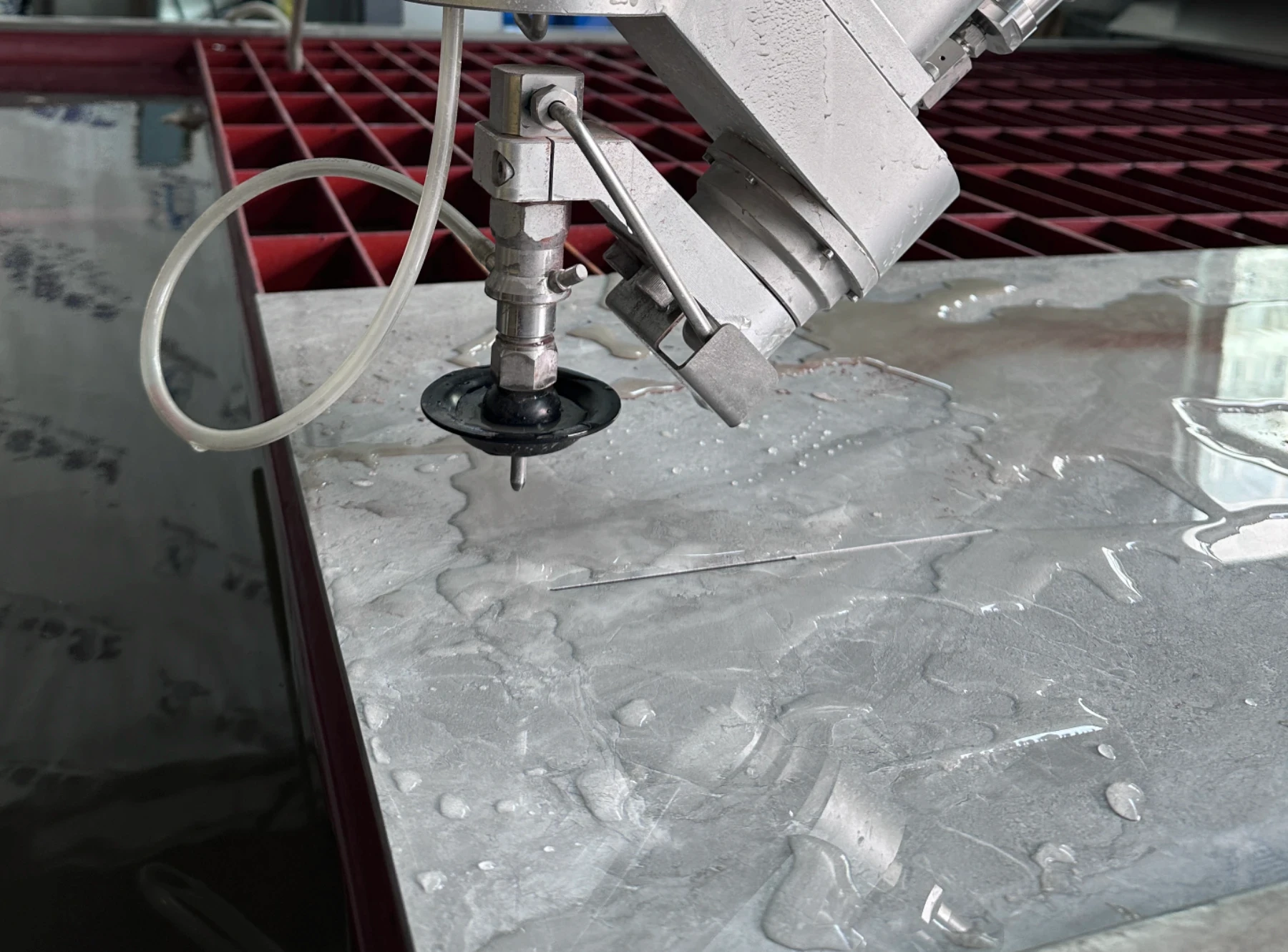

Understanding the Abrasive Water Jet Cutting Process

How does abrasive water jet cutting work?

High-pressure water (up to 94,000 psi) mixes with abrasive particles to create a cutting stream capable of slicing through virtually any material. The process combines the kinetic energy of pressurized water with the erosive power of abrasive materials.

Key components that determine performance:

- High-pressure pump: Generates consistent pressure for uniform cutting

- Cutting head: Mixes water and abrasive at precise ratios

- Abrasive delivery system: Controls particle flow for optimal cutting efficiency

- CNC control system: Ensures accurate path following and repeatability

Why choose abrasive water jet over traditional methods?

Unlike laser or plasma cutting, this cold cutting process produces no heat-affected zones, eliminating material distortion and maintaining structural integrity. The result is superior edge quality with minimal finishing requirements.

| Feature | Abrasive Waterjet | Laser Cutting | Plasma Cutting | CNC Milling |

|---|---|---|---|---|

| Heat Affected Zone | None | Minimal | Significant | Minimal (heat from friction) |

| Material Thickness | Up to 12" (300mm) | Up to 1" (25mm) for metals | Up to 6" (150mm) | Unlimited (multiple passes) |

| Cutting Speed | Slow to moderate | Fast for thin materials | Very fast | Moderate |

| Material Versatility | Nearly all materials | Limited with reflective/transparent materials | Conductive metals only | Most materials except very brittle |

| Surface Finish | Good to excellent, smooth | Excellent, may need minimal finishing | Rough, requires finishing | Excellent, depends on tooling |

Process advantages:

- Material versatility: Cuts metals, stone, ceramics, composites, and rubber

- Thickness capability: Handles materials up to 25-30cm thick

- Precision accuracy: Achieves 0.1mm tolerances consistently

- Complex geometries: Creates intricate shapes in a single operation

- No tool wear: Abrasive particles are consumable, not cutting tools

Abrasive water jet machining process steps:

- Material positioning and clamping

- Pressure system activation and stabilization

- Abrasive flow calibration

- Cutting path execution via CNC control

- Quality inspection and finishing (if required)

The process efficiency depends heavily on proper parameter selection including pressure settings, abrasive flow rates, and cutting speeds—factors that directly impact both quality and operating costs.

Abrasive Selection Guide: Choosing the Right Material

What abrasive is used in water jet cutting?

Garnet is the industry standard, accounting for over 95% of waterjet applications. This natural mineral offers optimal hardness, angular shape, and consistent particle size distribution for effective cutting performance.

Garnet mesh sizes and applications:

- 80 mesh: Fast cutting, rougher edge finish—ideal for thick materials and rapid production

- 120 mesh: Balanced performance—most common choice for general applications

- 150 mesh: Fine cutting, smooth finish—perfect for precision work and thin materials

Key factors affecting abrasive performance:

- Hardness rating: Garnet's 7.5-8.5 Mohs hardness provides excellent cutting ability

- Particle shape: Angular particles cut more efficiently than rounded ones

- Consistency: Uniform size distribution ensures predictable cutting results

- Purity: Low dust content reduces nozzle wear and improves cut quality

Abrasive consumption rates:

- Standard cutting: 0.5-1.0 pounds per hour

- Precision work: 0.3-0.7 pounds per hour

- Heavy-duty applications: 1.0-2.0 pounds per hour

Cost optimization strategies:

- Recycling systems: Reduce abrasive costs by 30-50% through particle reuse

- Flow rate adjustment: Optimize consumption based on material thickness

- Quality selection: Higher-grade abrasives often provide better value despite higher unit costs

How often should you change abrasive?

Fresh abrasive should be used for each cutting session. Unlike cutting tools, abrasive particles are single-use consumables that lose effectiveness after initial impact.

Alternative abrasives for specialized applications:

- Aluminum oxide: For non-ferrous metals requiring minimal contamination

- Glass beads: For delicate materials requiring gentle cutting action

- Steel grit: For specific industrial applications where garnet isn't suitable

Supplier evaluation criteria:

- Consistent particle size distribution

- Low moisture content

- Reliable supply chain

- Technical support and application guidance

Proper abrasive selection directly impacts cutting speed, edge quality, and operating costs—making it a critical factor in overall system performance.

Abrasive Waterjet Applications and Material Compatibility

Stone processing applications:

Abrasive water jet cutting stone delivers exceptional results across natural and engineered materials. Granite, marble, and quartz countertops benefit from the process's ability to create complex edge profiles and cutouts without cracking or chipping.

- Granite: Cutting speeds of 1-3 inches per minute for 2-inch thickness

- Marble: Higher speeds possible due to softer composition

- Engineered stone: Consistent cutting performance across resin-based materials

- Architectural stone: Precise cuts for decorative elements and structural components

Metal fabrication capabilities:

The technology excels in metal processing where traditional methods struggle with thickness or precision requirements.

- Stainless steel: Clean cuts up to 20cm thickness without heat distortion

- Aluminum: Fast cutting speeds with excellent edge quality

- Titanium: Ideal for aerospace applications requiring precise tolerances

- Tool steel: Maintains hardness properties through cold cutting process

Composite and advanced materials:

Water jet cutting abrasive materials extends to modern composites used in aerospace, automotive, and marine industries.

- Carbon fiber: No delamination or fiber damage

- Fiberglass: Clean cuts without resin melting

- Ceramic composites: Precise cutting of brittle materials

- Rubber and gaskets: Accurate shapes for sealing applications

Thickness capabilities by material

- Metals: Up to 2-20cm depending on material type

- Stone: 2-15cm for most applications

- Composites: 0.5-10cm typical range

- Ceramics: 0.1-5cm standard thickness

Production considerations

- Batch processing: Stacking thin materials increases efficiency

- Nesting optimization: Software maximizes material utilization

- Edge quality: Consistent finish reduces secondary operations

- Tolerance holding: Maintains 0.1mm accuracy across production runs

Material-specific cutting parameters: Each material requires optimized pressure, speed, and abrasive flow settings. Proper parameter selection ensures cost-effective operation while maintaining quality standards.

Industries benefiting from abrasive water jet machining applications:

- Aerospace component manufacturing

- Architectural stone fabrication

- Automotive parts production

- Marine equipment manufacturing

- Industrial machinery components

Understanding material compatibility helps determine whether abrasive waterjet cutting aligns with your production requirements and quality expectations.

Abrasive water jet Selection: Key Technical Factors

Pressure system selection:

Higher pressure doesn't always mean better performance. The optimal pressure depends on your material types and thickness requirements.

- 30,000 psi systems: Suitable for softer materials and thinner sections

- 60,000 psi systems: Industry standard for most applications

- 90,000 psi systems: Maximum cutting speed for thick, hard materials

Cutting head configuration:

The number of cutting heads directly impacts productivity and initial investment costs.

- Single-head systems: Lower cost, ideal for job shops and prototype work

- Multi-head systems: Higher productivity for production environments

- Taper compensation: Essential for maintaining perpendicular cuts in thick materials

Work table specifications:

Table size and design affect material handling efficiency and production flexibility.

- Standard sizes: 4x4, 6x12, 10x20 feet configurations

- Slat design: Supports various material shapes and sizes

- Catcher tank: Determines maximum cutting thickness capability

Automation and control systems:

Modern CNC control systems significantly impact ease of use and production efficiency.

- CAD/CAM integration: Direct file import and toolpath generation

- Automatic nesting: Software optimization for material utilization

- Remote monitoring: Real-time system status and diagnostics

- Preventive maintenance alerts: Reduces unplanned downtime

Pump technology considerations:

The high-pressure pump is the heart of any abrasive water jet cutting machine.

- Direct drive pumps: Higher efficiency, lower maintenance

- Intensifier pumps: Proven technology with extensive service network

- Pump life expectancy: 10,000-20,000 hours depending on maintenance

- Pressure consistency: Critical for cut quality and repeatability

Waterjet Advantages and Competitive Benefits

Cold cutting technology benefits:

Abrasive water jet cold cutting eliminates heat-affected zones, preserving material properties crucial for high-performance applications.

- No thermal distortion: Maintains dimensional accuracy

- Stress-free cuts: Prevents warping and cracking

- Material integrity: Preserves hardness and strength characteristics

- Consistent quality: Repeatable results across production runs

High-precision abrasive cutter capabilities:

Advanced systems deliver exceptional accuracy for demanding applications.

- Positioning accuracy: ±0.025mm repeatability

- Cutting tolerance: 0.1mm standard capability

- Surface finish: 125-250 μin Ra depending on cutting speed

- Perpendicularity: <0.1mm deviation over 10cm thickness

Complex geometry capabilities:

Single-setup machining reduces handling and improves accuracy.

- Sharp corners: 0.1mm radius internal corners possible

- Intricate patterns: Limited only by programming capability

- Stack cutting: Multiple parts in single operation

- Beveled edges: Programmable angle cutting

Environmental and safety advantages:

- No toxic fumes: Safe for enclosed manufacturing environments

- Minimal noise: Quieter than conventional cutting methods

- Recyclable abrasive: Environmentally responsible waste stream

- Reduced chemical usage: No cutting fluids or coolants required

DINOSAW Abrasive Water Jet Solutions

System specifications:

DINOSAW abrasive cutting systems deliver industrial-grade performance with user-friendly operation.

- Pressure range: 30,000-90,000 psi capability

- Cutting speeds: Optimized for various materials and thicknesses

- Precision standards: 0.1mm accuracy with excellent repeatability

- Automation options: Full CNC integration with advanced software

Proprietary abrasive delivery system:

Our patented abrasive water cutting system ensures consistent particle flow and optimal cutting performance.

- Precise flow control: Eliminates waste and improves cut quality

- Automatic calibration: Maintains optimal cutting parameters

- Clog prevention: Designed for continuous operation

- Easy maintenance: Simplified cleaning and adjustment procedures

Comprehensive service support:

- Installation and training: Complete commissioning and operator education

- Technical support: 24/7 assistance for production issues

- Parts availability: Comprehensive inventory for minimal downtime

- Maintenance programs: Scheduled service for optimal performance

Customer success examples:

- Aerospace manufacturer: 40% reduction in production time

- Stone fabricator: 60% improvement in material utilization

- Job shop: 3x increase in design complexity capability

Investment Decision Framework

Needs assessment checklist:

Before selecting an abrasive water jet machining system, evaluate these critical factors:

- Material types: Metals, stone, composites, or mixed materials

- Thickness range: Maximum and typical cutting thickness requirements

- Production volume: Parts per day/week/month expectations

- Accuracy requirements: Tolerance specifications for your applications

- Complexity level: Geometric complexity of typical parts

System sizing guidelines:

- Work envelope: 25% larger than your largest anticipated parts

- Pressure requirements: Based on thickest materials you'll process

- Automation level: Determined by production volume and labor costs

- Future expansion: Consider growing production needs

Supplier evaluation criteria:

- Technical expertise: Application knowledge and engineering support

- Service network: Local support and parts availability

- Training programs: Comprehensive operator and maintenance education

- Financial stability: Long-term support and warranty backing

Implementation timeline:

- Site preparation: 2-4 weeks for utilities and foundation

- Installation: 1-2 weeks for equipment setup and testing

- Training: 1 week for operators and maintenance staff

- Production ramp-up: 2-4 weeks to reach full productivity

Risk mitigation strategies:

- Demonstration cutting: Test your materials before purchase

- Phased implementation: Start with core applications, expand gradually

- Backup planning: Service agreements and spare parts inventory

- Operator cross-training: Multiple qualified personnel

FAQs of Abrasive Water Jet

What's the Difference Between Abrasive and Pure Water Jet Cutting?

Understanding the differences between abrasive and pure water jet cutting is essential for selecting the right process for your specific application needs.

| Feature | Pure Water Jet | Abrasive Water Jet |

|---|---|---|

| Cutting Mechanism | Water pressure alone | Water pressure + abrasive particles |

| Suitable Materials | Soft materials (foam, rubber, food, paper) | Hard materials (metals, stone, glass, ceramics) |

| Cutting Power | Lower (limited to materials under 1" thick) | Higher (can cut materials up to 12" thick) |

| Precision | Very high (±0.001" tolerance) | High (±0.003 - 0.005" tolerance) |

| Operating Cost | Lower (no abrasive consumption) | Higher (requires abrasive media) |

Which Abrasives Are Best for Water Jet Cutting?

The choice of abrasive significantly impacts cutting performance, surface finish quality, and operating costs.\

| Common Abrasive Materials | Particle Size Impact |

|---|---|

|

|

What materials can abrasive water jet cutting handle?

Abrasive water jet cutting can process a wide range of materials, including metals (steel, aluminum, titanium), stone (marble, granite), glass, ceramics, composites (carbon fiber, fiberglass), and more.

Why is garnet the most popular abrasive for water jet cutting?

Garnet is preferred for its optimal hardness, sharp edges, and recyclability. It offers a balance of cutting speed, edge quality, and low wear on equipment, making it cost-effective and efficient.

Is abrasive water jet cutting environmentally friendly?

Yes, it is an eco-friendly process that generates minimal waste, uses recyclable abrasives, and produces no harmful emissions or heat-affected zones.

What should I consider when buying an abrasive water jet machine?

Key factors include the machine’s capabilities (e.g., multi-axis cutting), the quality and availability of abrasives, after-sales support, and the reputation of the manufacturer, such as DINOSAW.

Take Action: Your Next Steps

Ready to explore abrasive water jet cutting for your operation? The technology offers proven benefits for manufacturers seeking precision, flexibility, and efficiency.

Get started today:

1. Free consultation: Our technical team will assess your specific requirements and recommend optimal solutions. No obligation—just expert advice tailored to your needs.

2. Material testing: Send samples for cutting trials. See firsthand how abrasive waterjet cutting performs with your materials and specifications.

3. System demonstration: Schedule an on-site or virtual demonstration. Watch the technology in action and ask questions about your specific applications.

4. Custom quotation: Receive detailed pricing for systems matched to your production requirements, including training, installation, and support.

Contact DINOSAW today:

Don't let outdated cutting methods limit your production capabilities. Join the thousands of manufacturers who've already discovered the competitive advantages of professional abrasive water jet cutting technology.

Your precision cutting solution awaits—contact us now to begin your evaluation process.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский