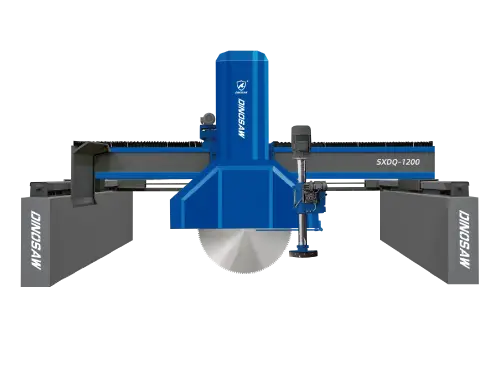

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

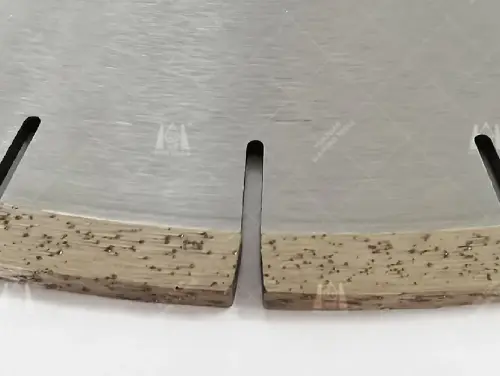

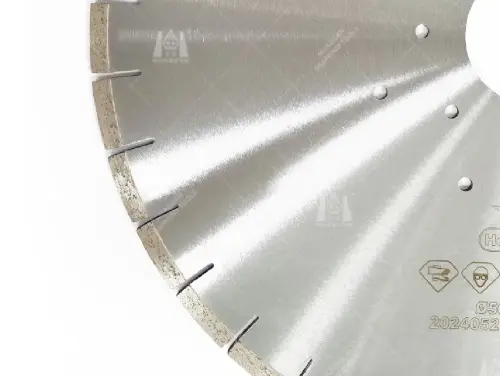

Horizontal Diamond Saw Blade for Granite & Marble

400-500mm

Compatible Materials & Products

Granite-Focused Horizontal Cutting | Productivity First

Granite > Block Cutting

Intro: Granite blocks are dense and highly abrasive, demanding a horizontal diamond saw blade for granite with stable tracking and coolant control.

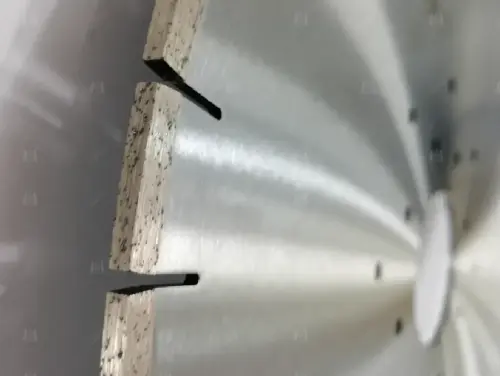

Process: Segmented metal bond design with tailored grit distribution and controlled water flow supports wet cutting, maintaining chip evacuation and kerf stability across long runs.

Benefit: Fast cutting and long life with fewer changeovers; smoother kerf quality and reduced edge chipping improve throughput and downstream finishing.

Granite > Slab Sizing

Intro: Granite slab sizing requires straight kerfs, minimal deviation, and consistent dimensional accuracy on production lines.

Process: Segment geometry and bond hardness are tuned for granite; wet cutting with defined coolant paths stabilizes heat and kerf integrity, supporting reliable sizing.

Benefit: Smooth kerf quality lowers surface roughness and rework; stable performance helps reduce scrap and improves continuous line efficiency.

Engineered Stone > Horizontal Milling

Intro: Engineered stone milling benefits from a metal-bond horizontal blade with controlled chip load and segment orientation.

Process: Segmented design and calibrated grit help maintain feed rate while preventing excessive chipping; wet operation improves evacuation and finish.

Benefit: Efficient material removal with cleaner finish and stable productivity; fewer pauses for maintenance improve overall line output.

Marble > Auxiliary Slab Cutting

Specs and options

Specifications customizable upon request.

| Diameter | Segment Dimension | Segment No. | Arbor | |

|---|---|---|---|---|

| Inches | mm | mm | pcs | mm |

| 16" | 400 | 40x5.5x5x8 | 26 | 50/60 |

| 18" | 450 | 40x5.5x5x8 | 28 | 50/60 |

| 20" | 500 | 40x6.6x5x8 | 33 | 50/60 |

Cut Granite Faster. Last Longer.

Metal-bond horizontal blade for granite lines.

High Productivity on Granite

Segmented metal bond and tuned grit deliver fast cutting and stable kerfs across long runs.

Long Tool Life

Bond hardness and geometry balance wear and sharpness to extend service life.

Consistent Kerf Quality

Optimized segment design reduces chipping and improves finish quality.

Custom Specifications

Diameter, bore, segment height, speed range placeholders; tailored to your line.

Wet Operation Preferred

Coolant channels and flow placeholders improve chip evacuation and blade life.

Certified Quality

CE marked, ISO 9001:2015; designed to EN 13236 safety requirements.

FAQs

Common Questions About Horizontal Diamond Blade

What is a horizontal diamond blade for granite and when to use it?

- What it means: “Horizontal” describes the blade’s cutting plane being parallel to the table/ground. The disk lies horizontally and slices the block layer‑by‑layer.

- How it differs: Unlike a vertical bridge saw that makes upright cuts, a horizontal diamond blade is mounted to cut flat layers (e.g., 20–60 mm slabs) with stable guidance and wet cooling.

- Typical uses: Quarry block slicing into slabs, slab sizing on production lines, underside trimming and horizontal milling for engineered stone.

How to choose bond hardness for different granite hardness/abrasiveness?

- Challenge: Granite varies widely in hardness and abrasiveness across quarries, which directly affects diamond exposure and wear rate.

- Choice: For hard and highly abrasive granite, a softer metal bond exposes fresh diamonds to keep speed; for medium or less abrasive granite, a harder bond improves longevity; segment height is chosen to balance durability and cost.

- Next step: Tell us your hardness range and throughput target so we can recommend the bond hardness and segment geometry that fit your process.

Segmented vs. continuous rim for block cutting vs. slab sizing?

- Scenario: Block cutting demands aggressive chip evacuation at higher feed rates, while slab sizing focuses on straight kerfs and dimensional accuracy.

- Guidance: Segmented blades clear chips quickly for block cutting and high feeds; refined segment geometry yields straighter kerfs for slab sizing; continuous rims are uncommon on granite due to heat build‑up and restricted chip flow.

- Next step: Provide your target feed rate and required kerf quality so we can set segment geometry and slot patterns that match the job.

What impacts speed, life, and TCO on granite lines?

- What matters: Bond hardness, segment height, stable wet cooling, and controlled feed determine speed and life on granite lines.

- Result: The right setup cuts faster with fewer dressings, improves kerf finish, and reduces rework, which lowers cost per square meter over time.

- Next step: Request an application review to quantify TCO and define operating ranges for RPM, linear speed, and coolant flow on your line.

When to dress and how to maintain a horizontal blade?

- Signs: Dress the blade when cutting speed drops, the surface appears glazed, or chip evacuation becomes uneven, indicating diamonds need exposure.

- Care: Inspect segment wear and core tension regularly, store blades flat and dry, and keep coolant clean to extend life and preserve finish quality.

- Next step: Request our maintenance checklist and material‑specific dressing guide to standardize upkeep on your line.

Certifications & Standards

Metal-bond horizontal blade for granite lines.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Get Your Granite Blade Quote & Lead Time

Send your specs (diameter/bore/segment height/speed range) to receive pricing and delivery.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Saw Blade Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский