Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

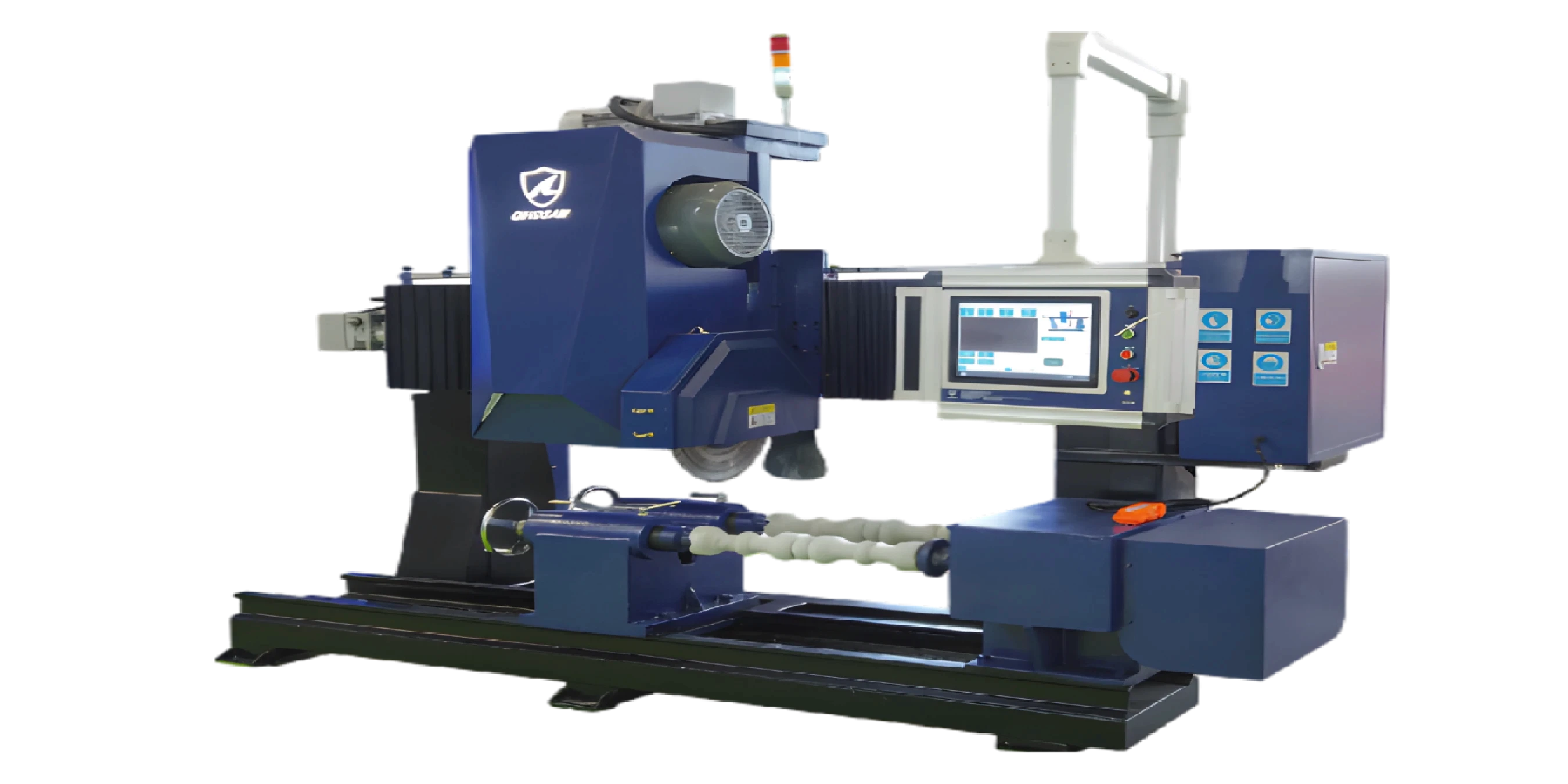

Tired of low-margin countertops? Discover how a CNC stone lathe transforms your fabrication business. Create high-profit architectural elements like columns & balusters.

While most fabricators fight over razor-thin countertop margins, smart shops are building six-figure businesses creating custom stone columns, ornate balusters, and stunning architectural pieces using CNC stone lathes.

This guide shows you exactly how to access high-value markets where customers pay premium prices for artistry, the specific products that generate 300%+ profit margins, and the streamlined workflow that makes complex projects profitable.

The Countertop Trap: Why Your Fabrication Shop Needs a New Revenue Stream

Most stone fabrication shops are stuck in what we call the "countertop trap"-competing on price instead of value, watching profit margins shrink year after year.

The Reality of Squeezed Countertop Profits in 2025

Here's what's happening in the standard countertop market: increased global competition has turned premium materials like granite and quartz into commodities. Fabricators find themselves constantly bidding against competitors, processing slabs efficiently, yet still struggling to hit desired profit margins.

This race to the bottom creates a vulnerable business model. You're always one bad quote away from losing a job, always one supply chain disruption away from squeezed margins.

The Hidden Goldmine: Architectural Stone Market Data

While countertop markets saturate, demand for unique architectural elements keeps growing. According to Grand View Research , the global decorative stone market reached $21.5 billion in 2024 and continues expanding as luxury residential and commercial projects prioritize distinctive, durable materials.

This market isn't about volume-it's about value creation. Clients pay for uniqueness, craftsmanship, and the ability to bring their architectural visions to life.

Profit Margin Reality Check: Slabs vs. Stone Columns

Let's look at the numbers that matter:

- 📉 Countertop Business: Purchase slab, cut and edge, sell with 20-30% margins while competing against dozens of other fabricators on price alone.

- 📈 Architectural Elements: Transform raw stone blocks into custom columns or balusters with profit margins reaching 100-300%+ based on artistry and complexity.

This shift moves you from commodity provider to specialized artisan. You set prices based on value created, not just material processed.

7 High-Value Architectural Elements You Can Start Selling Now

A CNC stone lathe transforms your workshop into an architectural art factory. Here are seven proven product lines that command premium pricing:

Classical & Modern Stone Columns

From robust Tuscan and Doric styles to sleek contemporary designs, custom stone columns are foundational elements in luxury construction. A CNC lathe can perfectly replicate classical architectural principles or produce minimalist designs with unmatched precision.

Intricate Balusters & Railings

Staircases and balconies become focal points in high-end properties when you can produce perfectly matched sets of ornate stone balusters. Each project transforms functional elements into major design statements.

Decorative Vases, Urns, and Planters

Custom stone planters and urns are essential for luxury landscaping projects. These pieces allow maximum creativity and often sell as standalone high-ticket decorative elements for both interior and exterior use.

Monumental Fountains and Water Features

A CNC lathe excels at creating complex, symmetrical fountain components-basins, pedestals, and decorative finials. These often become centerpiece projects for commercial courtyards and private estates.

Custom Fireplace Surrounds

Carved stone fireplace surrounds add immense value to homes. A CNC lathe machines complex profiles, mantels, and legs, letting you offer completely bespoke designs unavailable off the shelf.

Solid Stone Spheres and Finials

Large stone spheres for landscape design or decorative finials for gate posts deliver excellent returns on material and machine time. These are high-margin, relatively straightforward products to produce.

Historical Restoration & Replication Projects

This specialized niche offers exceptional profitability. Historical buildings often need exact replicas of weathered or damaged columns, balusters, or finials. Using 3D scanning and a CNC lathe, you can leverage digital fabrication techniques in historical preservation to create perfect reproductions-a service commanding significant premiums.

From Design to Profit: The Streamlined Dinosaw CNC Lathe Workflow

Creating complex 3D shapes might seem challenging, but modern CNC software has streamlined the entire process. Efficient workflow directly impacts profitability by minimizing programming time and eliminating costly errors.

Step 1: Effortless Design Input-From Custom CAD to Built-in Libraries

The Dinosaw system offers two efficient design paths. For unique projects, operators can directly import customer CAD drawings in standard formats (.dxf or .dwg). For common architectural pieces, they simply access the device's built-in library, select a template for a column or baluster, and input key parameters like height and diameter.

Everything happens through a visual interface, allowing operators to see a complete 3D model before cutting any stone.

Step 2: Intelligent Programming with Automatic Tool Compensation

Once the design loads, the software's intelligence takes over. Automatic tool compensation constantly calculates tool position and wear, making real-time cutting path adjustments. This ensures final dimensions perfectly match the design, preventing errors that could ruin expensive marble or granite blocks.

This represents a significant advancement over older CNC vs. PLC systems , delivering far greater precision and reliability.

Step 3: Automated Carving & The "One-Step Finish" Advantage

Here's where the Dinosaw CNC Lathe creates real competitive advantage. After automated carving shapes the piece, our machine deploys its unique surface grinding and polishing function. The saw blade's side methodically sweeps across the stone surface, creating a consistent, high-quality honed finish.

For many architectural products where natural or matte looks are desired, pieces finish right on the machine-eliminating secondary polishing steps and dramatically reducing labor costs.

Finding Your Buyers: How to Market High-Value Architectural Stone

Creating beautiful architectural elements is only half the equation. Success requires connecting with the right buyers in this relationship-driven market that values expertise and quality above everything else.

Target Market 1: Architects & Interior Designers

These professionals are your primary channel to high-end projects. They design luxury buildings and specify materials. Build a portfolio showcasing your work and present it to local and regional firms. Offer custom samples and position yourself as a technical partner who brings their visions to life.

Target Market 2: High-End Custom Home Builders

These builders work on projects with larger budgets where unique features become key selling points. They provide direct access to homeowners wanting custom stone fireplaces, columns, and staircases.

Target Market 3: Landscape Architecture Firms

For outdoor projects, landscape architects are essential specifiers. The American Society of Landscape Architects (ASLA) 2024 trends report shows strong demand for durable, natural materials in outdoor living spaces. Your stone urns, fountains, and spheres perfectly serve this market.

Target Market 4: Historical Preservation Committees

Connect with local and national preservation groups. Getting listed as a preferred supplier for historical restoration projects leads to highly profitable, prestigious contracts that often generate referrals to other luxury projects.

Why Dinosaw's Lathe is the Smarter Investment for Your Business

Choosing the right machine goes beyond technical specifications. You're investing in a solution that delivers reliability, efficiency, and clear return on investment.

Calculating Your ROI: A Simple Framework

When evaluating this investment, look beyond the initial purchase price. Your ROI depends on:

- Increased Profit Margins: Shifting from countertop margins (20-30%) to architectural element margins (100%+)

- Reduced Labor Costs: Automation of carving and finishing cuts man-hours per project

- Material Waste Reduction: High-precision software minimizes errors, saving expensive stone blocks

For detailed financial evaluation, review our complete cost-benefit analysis showing real-world ROI scenarios.

Dinosaw's Competitive Edge: Software That Saves Time and Money

Our CNC stone lathe is engineered for precision and superior operational efficiency. Here's how our integrated software creates tangible competitive advantages:

Flexible Design Input

Directly import custom CAD files or use our extensive built-in library for fast, parametric adjustments, serving any client need efficiently.

⚡ Integrated Finishing

Unique blade-side grinding reduces or eliminates secondary polishing, dramatically cutting labor costs and production time.

🔧 Guaranteed Precision

Automatic tool compensation eliminates guesswork and costly errors, ensuring perfect pieces and minimized material waste.

Visual Control Interface

Fully visual interface lets operators see exactly what they're making, simplifying operation and reducing training time significantly.

Frequently Asked Questions

Is a CNC stone lathe a profitable investment?

Absolutely. A CNC stone lathe is highly profitable for shops targeting high-margin markets. While countertop profits typically stay below 30%, custom architectural elements like columns or balusters command margins of 100-300% due to craftsmanship value and customization.

The investment pays for itself by enabling high-value item production, and Dinosaw's automated features boost profitability by reducing labor costs and material waste.

What type of stone works best for architectural columns and balusters?

The best stones combine aesthetic appeal, durability, and workability:

- Marble: Prized for classic beauty and veining, ideal for interior columns and decorative pieces

- Limestone: Offers uniform, classical appearance and easy workability, perfect for fireplace surrounds and balustrades

- Travertine: Known for unique pitted texture, suitable for both interior and exterior applications

- Granite: Extremely durable and weather-resistant, top choice for exterior columns and high-traffic areas

The Natural Stone Institute provides a comprehensive guide to stone varieties to help select perfect materials for your projects.

How long does it take to make a stone column on a CNC lathe?

Production time varies by size, stone hardness, and design complexity, but a typical residential-sized marble column (8 feet tall, 1 foot diameter) can be turned in 6-10 hours.

Dinosaw's efficient software and robust construction optimize for speed, while the integrated grinding function saves an additional 2-4 hours of secondary polishing work, significantly shortening total production cycles.

What skills does a CNC stone lathe operator need?

Operators need basic computer literacy and understanding of stone properties. Modern systems like Dinosaw's are designed for user-friendliness. Key skills include:

- Importing or selecting designs from the library

- Setting up stone blocks on the machine

- Overseeing automated cutting processes

The software handles complex calculations, so extensive manual programming knowledge isn't required for most jobs, dramatically reducing training barriers.

Can you make complex, non-symmetrical shapes on a stone lathe?

While traditional lathes handle symmetrical, round objects, advanced CNC stone lathes often have additional axes of motion (becoming turning centers). This allows milling, fluting, and carving non-symmetrical details onto turned pieces.

For fully non-symmetrical sculptures, a 5-axis CNC machining center would be more appropriate.

How much space is required for a CNC stone lathe?

Footprint varies by model, but a medium-sized lathe handling columns up to 8-10 feet long typically requires floor space of roughly 20 ft x 10 ft (6m x 3m), including clearance for loading and operation.

Always consult the machine's technical specifications for exact dimensions and foundation requirements before installation.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский