Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

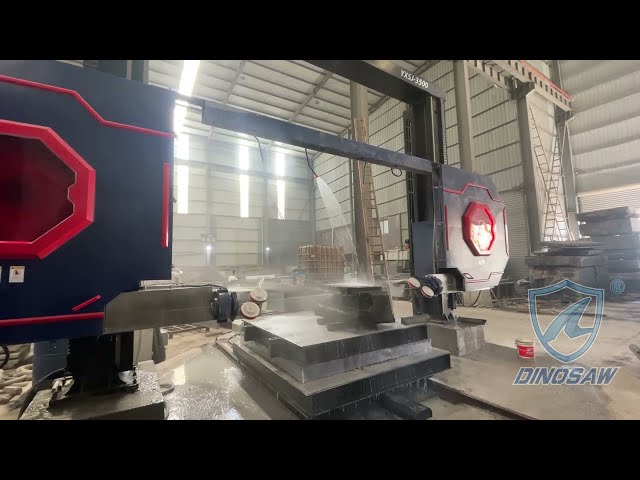

Granite curved panel cutting case study using a CNC wire saw by Dinosaw Machinery, focusing on arc accuracy, surface consistency, and stable processing for architectural applications.

▶

▶Case Snapshot

Material: Granite

Processing Method: Cutting

Typical Application: Curved granite panels for architectural decoration

Applicable Markets: Architectural stone fabrication and premium construction projects

Processing Focus: Arc accuracy and surface consistency on curved granite panels

Associated Product: Dinosaw CNC Wire Saw Machine

Application Context for Curved Granite Panel Production

Curved granite panels are commonly used in architectural projects where natural stone is integrated into rounded façades, columns, and decorative wall elements.

Unlike flat stone slabs, curved panels require controlled shaping to achieve consistent curvature while maintaining surface quality.

In production environments, fabricators are often required to process multiple panels with identical curvature to ensure alignment during installation, making repeatability a key requirement in curved granite applications.

Practical Challenges in Cutting Granite Curved Panels

Processing curved granite panels introduces challenges beyond standard straight cutting.

Workshops handling similar applications typically face issues such as:

Maintaining consistent curvature across multiple panels

Controlling cutting accuracy along long arc paths

Preventing surface damage or uneven edges during curved cutting

Managing cutting stability on hard, dense granite material

Ensuring repeatability for panels used in the same installation area

These challenges make curved granite cutting more sensitive to process control than conventional slab processing.

Workshop Insights from Curved Granite Cutting Operations

What makes granite curved panel cutting more demanding than straight cuts?

Curved cutting requires the cutting path to follow a continuous arc rather than a straight line.

In hard materials like granite, even small deviations can affect the final curvature, especially when multiple panels need to match the same radius.

Maintaining a smooth cutting path is essential to avoid visible inconsistencies along the curved edge.

Why is wire saw cutting suitable for producing curved granite panels?

Wire saw cutting is well suited for curved panel production because it allows flexible path control along arc geometries.

Unlike rigid blade-based cutting methods, the wire saw can follow complex curves with smoother transitions, reducing localized stress on the granite.

In this application, the CNC wire saw solution provided by Dinosaw Machinery supported controlled arc cutting while maintaining surface consistency.

What do operators focus on most during the curved cutting process?

Operators pay close attention to path accuracy and cutting stability throughout the arc.

Ensuring consistent cutting conditions along the entire curved path is critical, particularly when working with thick granite panels.

Proper material positioning and secure support are also essential to prevent vibration or movement during cutting.

How is acceptable quality judged for finished curved granite panels?

From a production perspective, curved granite panels are considered acceptable when their curvature matches design specifications and edges remain clean and uniform.

Panels must also align correctly with adjacent pieces during dry fitting, without requiring excessive corrective work.

These criteria are commonly used in architectural stone fabrication to ensure both visual quality and installation efficiency.

How the Granite Curved Panel Cutting Process Was Handled

In this case, granite slabs were positioned and cut following predefined curved paths.

The cutting process emphasized stable movement along the arc to avoid sudden changes in cutting load that could affect surface quality.

The CNC wire saw system from Dinosaw allowed consistent execution of curved cuts across multiple panels, supporting repeatable production for architectural applications.

Observed Results in Granite Curved Panel Processing

Based on the observed cutting process:

Curved granite panels were produced with consistent arc geometry

Edge conditions remained smooth and uniform

Panels were suitable for downstream finishing and installation

Cutting stability was maintained across multiple curved panels

These outcomes meet typical production expectations for curved granite architectural elements.

Who This Case Is Relevant For

This case is particularly relevant for:

Stone fabricators producing curved granite panels for architectural projects

Workshops handling façade elements, columns, or rounded stone features

Manufacturers requiring repeatable curved cutting on hard stone materials

Facilities evaluating CNC wire saw solutions from Dinosaw Machinery for curved stone processing

If you are processing granite panels with curved geometries and require consistent arc accuracy, this case provides a practical reference scenario.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский