Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A complete guide to CNC stone router costs in 2025. This article breaks down the prices of different CNC stone routers and the key factors that affect the total investment.

Introduction: Understanding the Real Investment in a CNC Stone Router

If you're in the stone fabrication business, you know that precision and efficiency are everything. A CNC stone router is a game-changing investment, capable of transforming granite slabs into intricate countertops and marble blocks into detailed sculptures. But the first question on every business owner's mind is: "How much does a CNC stone router really cost?"

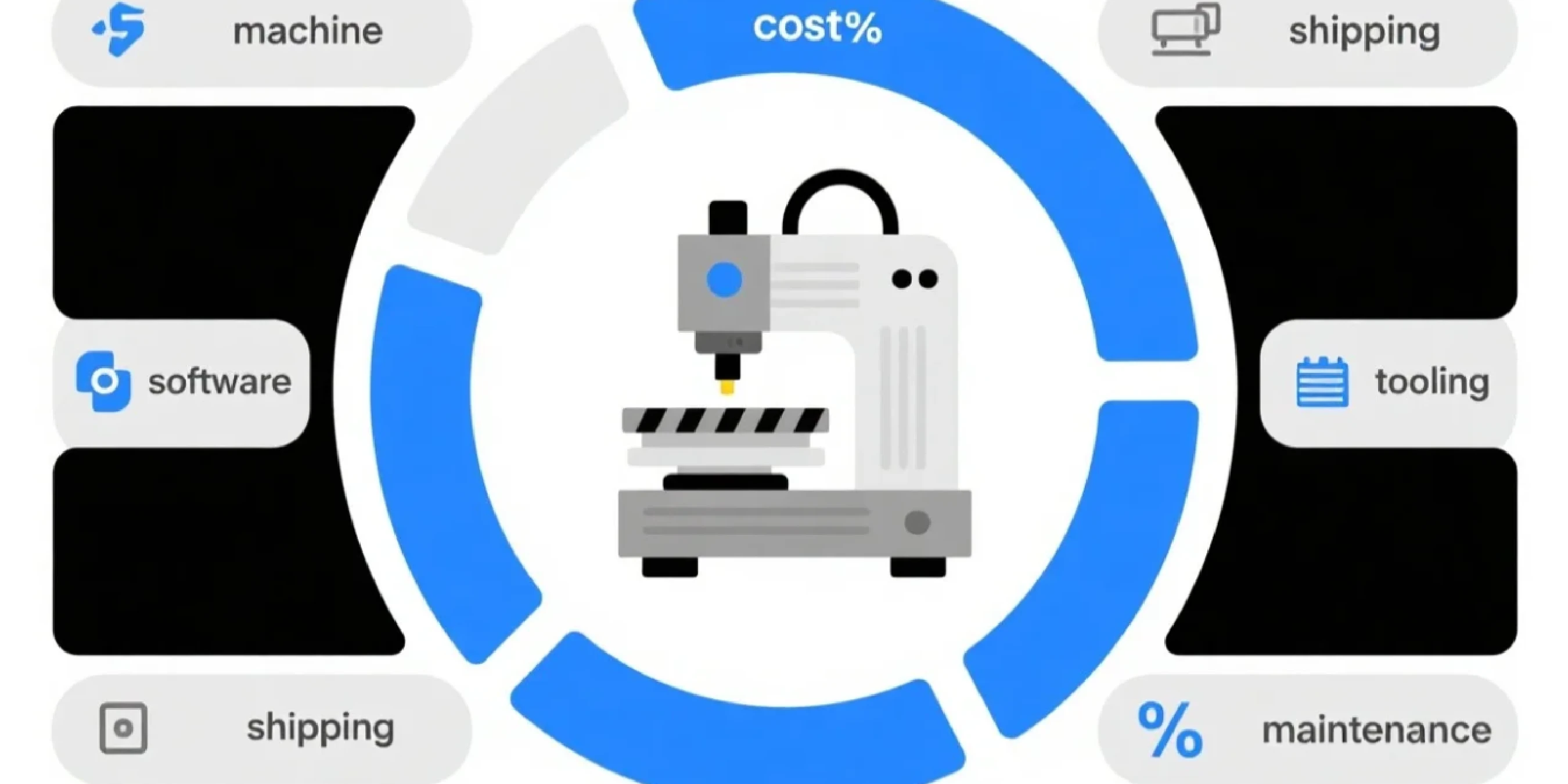

The answer isn't a simple number. The price on an invoice is just the beginning. The total cost of ownership involves the machine's configuration, software, shipping, and ongoing operational expenses. This guide will break down every factor, providing you with a clear and realistic budget framework for your 2025 investment. We'll help you understand not just the price, but the true value of adding a high-performance CNC stone router to your workshop.

Price Tiers: Finding the Right Machine for Your Business Scale

CNC stone routers are not one-size-fits-all. Their prices vary dramatically based on their size, structural integrity, and production capacity. Here’s a breakdown of the typical market price ranges:

Entry-Level & Small-Scale CNC Stone Routers ($4,000 - $15,000)

- Best For: Small workshops, tombstone engraving, detailed craftwork, or businesses new to CNC technology.

- Typical Features: Smaller work areas, simpler control systems, and manual tool changes. They have the capability for basic engraving and cutting on softer stones but may struggle with high-volume production on hard materials like quartzite.

Professional-Grade CNC Stone Routers ($20,000 - $60,000)

- Best For: Established countertop fabrication shops and professional monument makers.

- Typical Features: Standard work tables in sizes like 1300x2500mm (approx. 4x8 ft) or 3200x2000mm (approx. 10.5x6.5 ft), heavier-duty steel frames for rigidity, and powerful water-cooled spindles (5.5kW to 7.5kW). They often include an automatic tool changer (ATC) and robust industrial control systems. The Dinosaw Machine CNC Stone Router series is a prime example in this category, engineered for precision and durability in daily production environments.

Industrial-Grade Heavy-Duty CNC Stone Routers ($60,000+)

- Best For: Large-scale manufacturing facilities with high production demands.

- Typical Features: Massive, reinforced structures, high-end spindles from trusted suppliers, advanced 4-axis or 5-axis capabilities for complex 3D carving, and full integration with automated loading/unloading systems.

Key Factors That Drive the Final Cost

Beyond the basic size, several critical components determine the final price tag. Understanding these will help you configure a machine that fits your needs without overspending.

Spindle Power and Type

A wood router spindle is not a stone router spindle. Stone carving requires high torque and effective cooling. A high-frequency, water-cooled spindle is non-negotiable. Upgrading from a standard 5.5kW spindle to a 9kW spindle for harder materials like granite will increase the cost but significantly boost performance.

Control System & Software

The machine's "brain" is crucial. A basic handheld controller is cheaper, while a dedicated industrial PC-based controller offers better stability, speed, and ease of use. Additionally, you'll need professional CAD/CAM software to design your projects. Some machine packages include basic software, but high-end 3D carving software from providers like VCarve or Alphacam is a separate, significant investment.

The Frame and Gantry Structure

This is critical for stone. Cutting stone generates immense vibration. A machine with a thick, heavy-duty, welded steel frame will cost more than one with a lighter frame, but it's essential for achieving a smooth finish and maintaining accuracy over years of use.

Tooling and Water Management

An Automatic Tool Changer (ATC) can add thousands to the cost but saves invaluable time in production. Furthermore, a robust water circulation and filtration system is vital for cooling diamond tools and managing stone dust. Don't underestimate the cost of setting this up correctly.

Beyond the Machine: Budgeting for "Hidden" Costs

The initial purchase is only part of the investment. Smart business owners budget for these additional expenses:

The initial purchase is only part of the investment. Smart business owners budget for these additional expenses:

Shipping, Rigging, and Installation

A heavy-duty stone router can weigh several tons. Budget for freight shipping, professional rigging services to move it into your shop, and on-site installation and calibration by a technician.

Diamond Tooling

Your machine is useless without the right tools. A starter set of high-quality diamond bits for engraving, cutting, and polishing can cost anywhere from $500 to $2,000.

Training and Maintenance

Proper training for your team is essential for safety and efficiency. Factor in the cost of initial training and a regular maintenance schedule for consumables like lubricating oil, guide rail wipers, and water pump filters.

From the Field: FAQ

We searched stone fabricator forums to answer the most common questions new buyers have:

Can I use a wood CNC router for stone?

It is highly discouraged. A wood router lacks the structural rigidity and the essential water cooling system required for stone. Attempting to do so will damage the machine and produce poor results.

What is the biggest "hidden cost" I should prepare for?

Most experienced fabricators point to two things: proper electrical and water setup for the machine, and the initial investment in a comprehensive set of high-quality diamond tools.

How often do I need to perform maintenance?

Daily maintenance includes cleaning the machine and checking the water system. Weekly checks on lubrication for the guide rails are crucial. A full mechanical check-up should be done quarterly.

Conclusion: Making a Smart, Profitable Investment

The cost of a CNC stone router is a spectrum, ranging from a few thousand dollars for a basic machine to over six figures for an industrial workhorse. The key is not to find the cheapest machine, but the one with the best value for your specific application.

By understanding the factors that influence price—from the machine's physical structure to the software that runs it—you can make an informed decision. An investment in the right machine, like a robust and reliable unit from Dinosaw Machine, will pay for itself through increased productivity, higher-quality products, and expanded business capabilities for years to come.

Ready to find the perfect CNC solution for your workshop? Contact a Dinosaw Machine expert today for a personalized consultation and quote based on your unique production needs.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский