Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

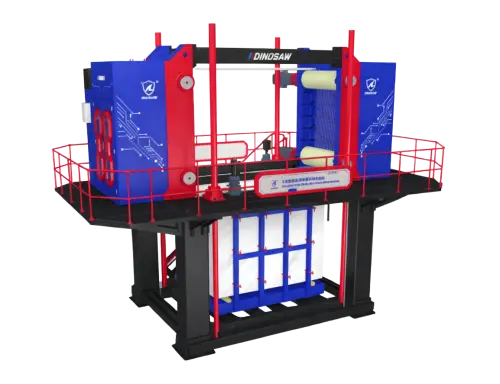

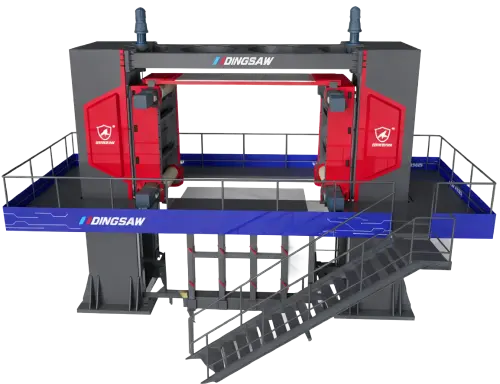

Diamond Thin Multi-Wire Saw for Factory Production

DS‑1212H

Compatible Materials & Products

Precision Thin Slicing for Hard‑Brittle Materials

Composite SiC Block > Wafers

|

|

The demand for high-performance semiconductor wafers made from silicon carbide (SiC) composites is rapidly growing. This advanced material requires a cutting solution that guarantees minimal subsurface damage and high geometric accuracy for optimal device performance, especially during pilot runs. The DINOSAW lab multi-wire saw is specifically engineered for SiC wafer slicing in factory R&D settings. Its high-precision tension control system and up-feed mechanism ensure low-damage, warp-free cutting, which is critical for producing reliable semiconductor wafers. This process significantly enhances material yield during process validation. Our machine's technical advantage lies in its ability to maintain stable wire speed and tension, preventing micro-cracks and delivering a superior surface finish. This precision slicing capability reduces the need for extensive lapping and polishing, saving time and cost in small-batch production. The result is perfectly sliced SiC wafers with exceptional thickness uniformity and surface quality, ready for downstream processing. This boosts throughput and yield in demanding semiconductor fabrication environments, validating the process for mass production. By integrating our small multi-wire saw, factory pilot lines can accelerate R&D and validate production processes for next-generation power electronics, unlocking new commercial opportunities with a reliable cutting technology. |

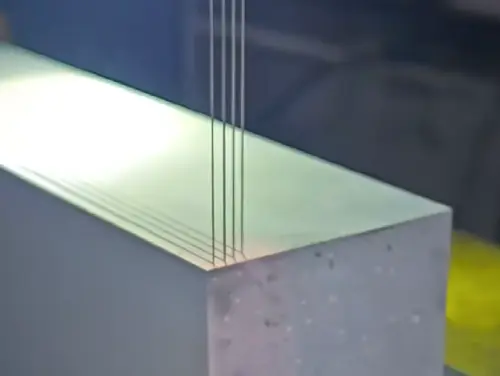

Optical Glass > Precision Lenses

|

|

The optical industry requires flawless glass components for high-precision lenses, prisms, and filters. Traditional cutting methods often introduce thermal stress and micro-cracks, compromising optical performance and increasing scrap rates during pilot runs. The DINOSAW multi-wire saw provides a superior solution for optical glass slicing. Its precise up-feed cutting and diamond wire technology minimize thermal impact, delivering clean, stress-free cuts. This machine is ideal for creating thin optical glass slices with unparalleled accuracy for trial production samples. The core technology ensures exceptional dimensional stability and flatness (e.g., ±0.02mm), critical for maintaining the refractive index and light transmission properties of the material. This precise control eliminates variability and ensures consistent quality for pilot production. The application yields perfectly uniform optical glass blanks with pristine surfaces, significantly reducing subsequent grinding and polishing efforts. This leads to faster production cycles and higher profitability for optical component manufacturers. By adopting our thin multi-wire saw for processing optical materials, your factory can produce top-tier pilot samples for lenses and components, meeting the stringent demands of the consumer electronics, medical, and defense industries. |

Alumina Ceramics > Substrates

|

|

Alumina ceramics are vital for electronic substrates and components due to their excellent thermal and electrical insulation properties. However, their hardness and brittleness make them challenging to machine without causing chipping or fractures. The DINOSAW thin multi-wire saw is expertly designed for slicing alumina ceramics with high precision. Using a fine diamond wire and a gentle up-feed motion, the machine minimizes mechanical stress, delivering clean cuts with excellent edge quality for substrates. Its advanced tensioning system and rigid frame provide the stability needed for low-damage cutting. This technology ensures tight dimensional tolerances and superior flatness, which are essential for high-density circuit printing and component mounting. This results in high-quality ceramic substrates with consistent thickness and defect-free surfaces. This reliable machining process significantly improves the yield of valuable components and reduces material waste during production. By leveraging this precision slicing machine for alumina ceramic processing, R&D teams and manufacturers can produce reliable, high-performance substrates for advanced electronics, enhancing their competitive edge in a demanding market. |

Graphite Block > Anode Materials

|

|

High-purity graphite is a key material for battery anodes and other energy applications. The slicing process must be precise and clean to ensure optimal electrochemical performance and avoid contamination of the final anode materials. The DINOSAW multi-wire saw excels at slicing graphite blocks with precision. Its up-feed cutting method and specialized diamond wire ensure smooth surfaces and prevent chipping, preserving the structural integrity of the anode materials for consistent performance. The machine's technology focuses on controlled, low-impact cutting, which is ideal for the soft and abrasive nature of graphite. The constant tension control prevents wire vibration, resulting in highly accurate, uniform slices. This process delivers high-quality graphite anode slices with minimal material loss and excellent surface finish. This precise fabrication is critical for achieving high energy density and long cycle life in modern batteries. Implementing our thin multi-wire saw for graphite processing allows large industrial labs and battery manufacturers to refine their anode materials and accelerate the development of next-generation energy storage solutions with a reliable, efficient technology. |

Specs and options

Specifications customizable upon request.

| Item | Unit | DS-1212H |

|---|---|---|

| Feed type | / | Up-feed |

| Cutting feed rate | mm/h | 100-280 |

| Diamond wire diameter | mm | 0.35-0.8 |

| Slab thickness | mm | 2-30 |

| Cutting tension | N | 0-300 |

| Table lift travel | mm | 2000 |

| Wire storage | m | - |

| Roller diameter | mm | 350-450 |

| Main motor power | kW | 60x4 |

| Max workpiece size (LxWxH) | mm | 1200x1200x1200 |

| Machine weight | T | 35 |

| Overall dimensions | mm | 8330x5363x5200 |

Option | Function | Recommendation |

|---|---|---|

Rotating table | Rotate block without re-hoisting; adjust cutting angle | Recommended for irregular blocks / non-standard angles |

Transfer cart (aux table) | Parallel loading/unloading beside main table | Must‑have for peak throughput |

Extended rails | Longer cart travel space for multi‑cart / long pieces | Pair with transfer cart or when layout needs longer travel |

Spindle box set (drive/idler) | Spare assembly for quick swap to cut downtime | Buy as spare if production loss is costly |

Roller | Key wire‑net part; different materials/coatings affect wear/inertia | CF+PU for high speed/energy saving; iron/aluminum for budget |

Wire welder | Repair broken wire; fast wire recovery | Essential for most users |

Roller lathe | Pre‑recoat turning & alignment; reduce run‑out/vibration | Own in high‑utilization plants; outsource if low |

Tension wheel | Keep wire tension stable; core force element | Stock as consumable; set preventive replacement & calibration |

Guide wheel rubber ring | Protect wire & guide; improve friction & stability | Track wear & replace early for stable cutting quality |

Wire winder | Fast uniform winding; control pitch & initial tension | Standard for multi‑wire; best with wire welder |

Advanced engineering meets practical factory pilot needs.

Precision Slicing, From Pilot Line to Production.

Unmatched Slicing Precision

Constant tension control (±0.5 N) and a rigid frame ensure minimal vibration for superior accuracy.

Maximize Material Yield

Ultra-thin kerf loss (as low as 0.5mm) saves valuable materials, crucial for expensive samples.

Versatile Material Capability

Optimized for a wide range of hard, brittle materials from SiC and sapphire to special ceramics.

Low-Damage Cutting

The up-feed mechanism and controlled process minimize subsurface damage and micro-cracks.

Compact Design

Delivers industrial performance in a smaller footprint, perfect for factory R&D centers and pilot lines.

Rapid Process Validation

Quickly test and optimize cutting parameters before scaling to full production.

FAQs

Common Questions About the Pilot-Line Multi-Wire Saw

What is a pilot-line multi-wire saw used for?

How does up-feed cutting benefit brittle material slicing?

What materials can this small multi-wire saw cut?

What is kerf loss and why is it important in R&D?

Is it difficult to set up cutting parameters for new materials?

How to choose the right diamond wire diameter for my material?

Choosing the right diamond wire diameter involves balancing cutting efficiency, material waste, and surface quality. Generally, a thinner wire (e.g., 0.35–0.45 mm) creates a smaller kerf, maximizing the yield from expensive materials like SiC or sapphire, which is ideal for pilot-line thin slicing. A thicker wire (e.g., 0.6–0.8 mm) offers greater durability and is suitable for less critical applications or harder materials where breakage is a concern. For the DS-1212H, we recommend starting with the following guidelines for your diamond wire selection:

- For Ultra-High Precision (e.g., optical glass): Use a 0.35 mm wire to achieve the best surface finish and minimal kerf loss.

- For General R&D (e.g., ceramics, SiC): A 0.45 mm wire offers a good balance of precision and wire longevity.

- For Exploratory Cutting (e.g., new composites): Start with a 0.6 mm wire for added robustness during process parameter validation.

What causes wire breakage and how can I prevent it?

Wire breakage in a multi-wire saw is often caused by improper tension, excessive feed rates, or poor debris removal. The DINOSAW DS-1212H minimizes this risk with its patented constant tension control system (±0.5 N), which prevents sudden tension spikes that could snap the wire. To prevent breakage, adhere to these best practices for diamond wire slicing:

- Verify Tension Settings: Ensure the tension is set according to the wire diameter and material hardness.

- Optimize Feed Rate: Avoid aggressive feed rates, especially when starting a cut or encountering inconsistencies in the material.

- Ensure Proper Cooling: Check that the coolant flow is sufficient to clear debris from the kerf, as buildup can cause the wire to snag and break.

- Inspect Guide Wheels: Regularly check guide wheel grooves for wear, as worn wheels can damage the wire.

What is the typical maintenance schedule for consumables?

Proper maintenance of consumables is key to consistent performance. While the exact schedule depends on usage intensity and materials, a general maintenance plan for a thin multi-wire saw is essential for pilot production uptime. Here is a recommended schedule for key components:

- Diamond Wire: Replace based on cutting performance decline or after a set number of cutting hours specified for your process. The use of a welding machine can extend its life.

- Rollers : After approximately 6 re-grooving cycles on a roller lathe, a full re-coating is necessary. One re-coating typically lasts for about 160,000 square meters of cutting.

- Guide Wheel Rubber Rings: Inspect weekly for wear and replace proactively to prevent wire slippage and maintain cutting accuracy.

- Tension Wheels: Calibrate sensors periodically and inspect wheels for wear as part of a quarterly preventive maintenance check.

How do I balance slice thickness and surface quality?

Certifications & Standards

Precision Slicing, From Pilot Line to Production.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to accelerate your material innovation?

Contact our experts to learn how the DINOSAW multi-wire saw can elevate your R&D capabilities.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский