Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

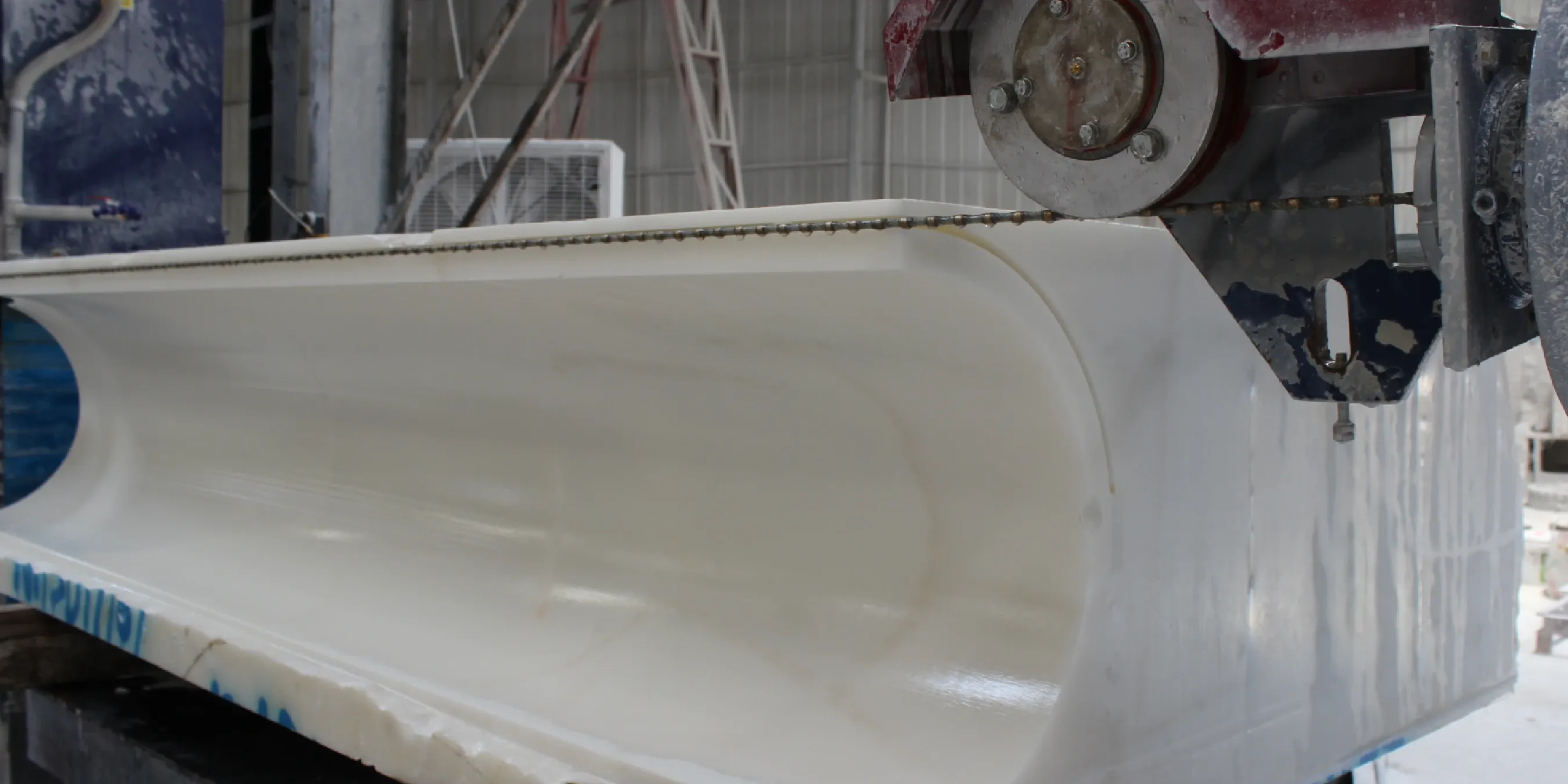

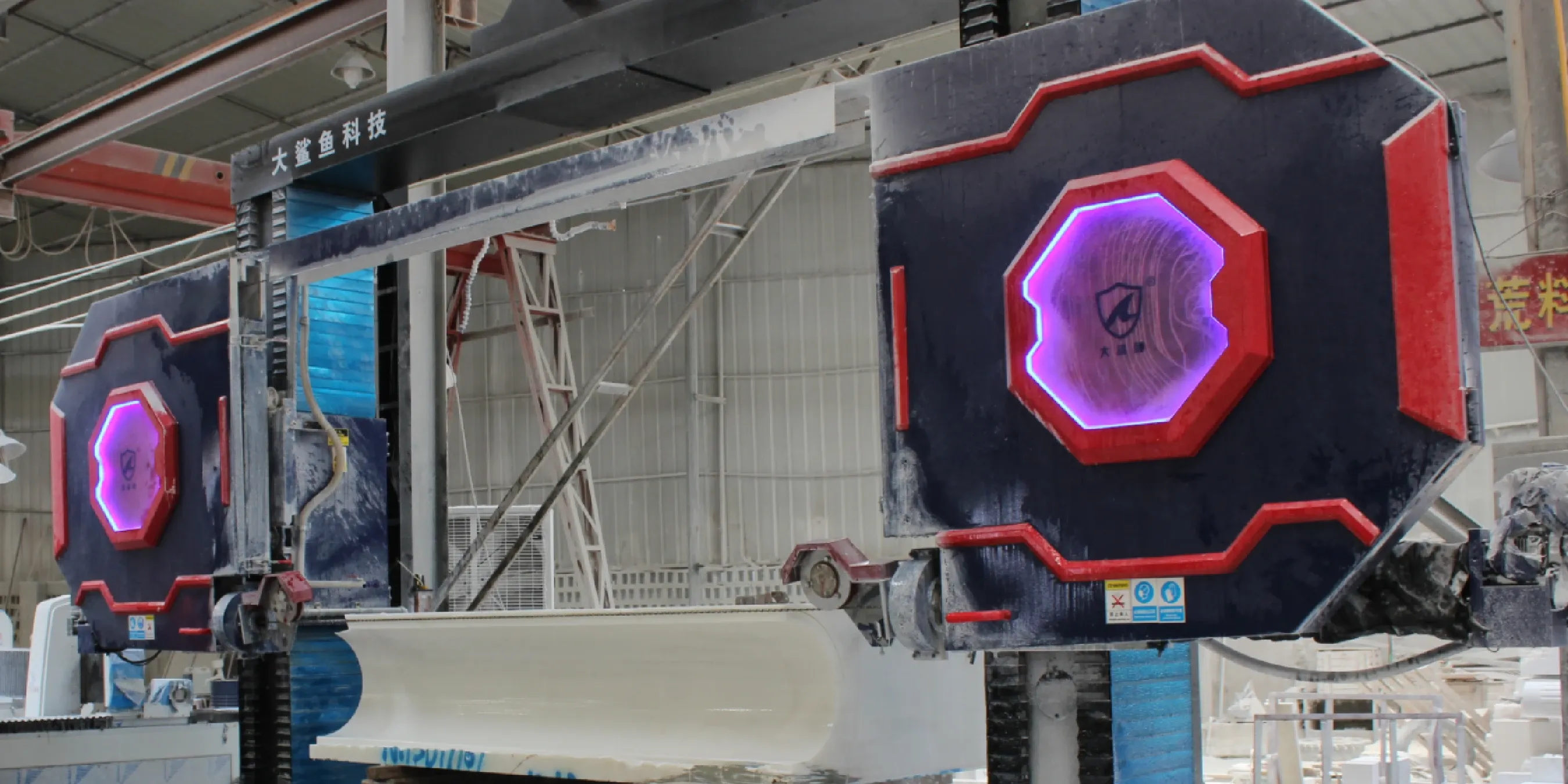

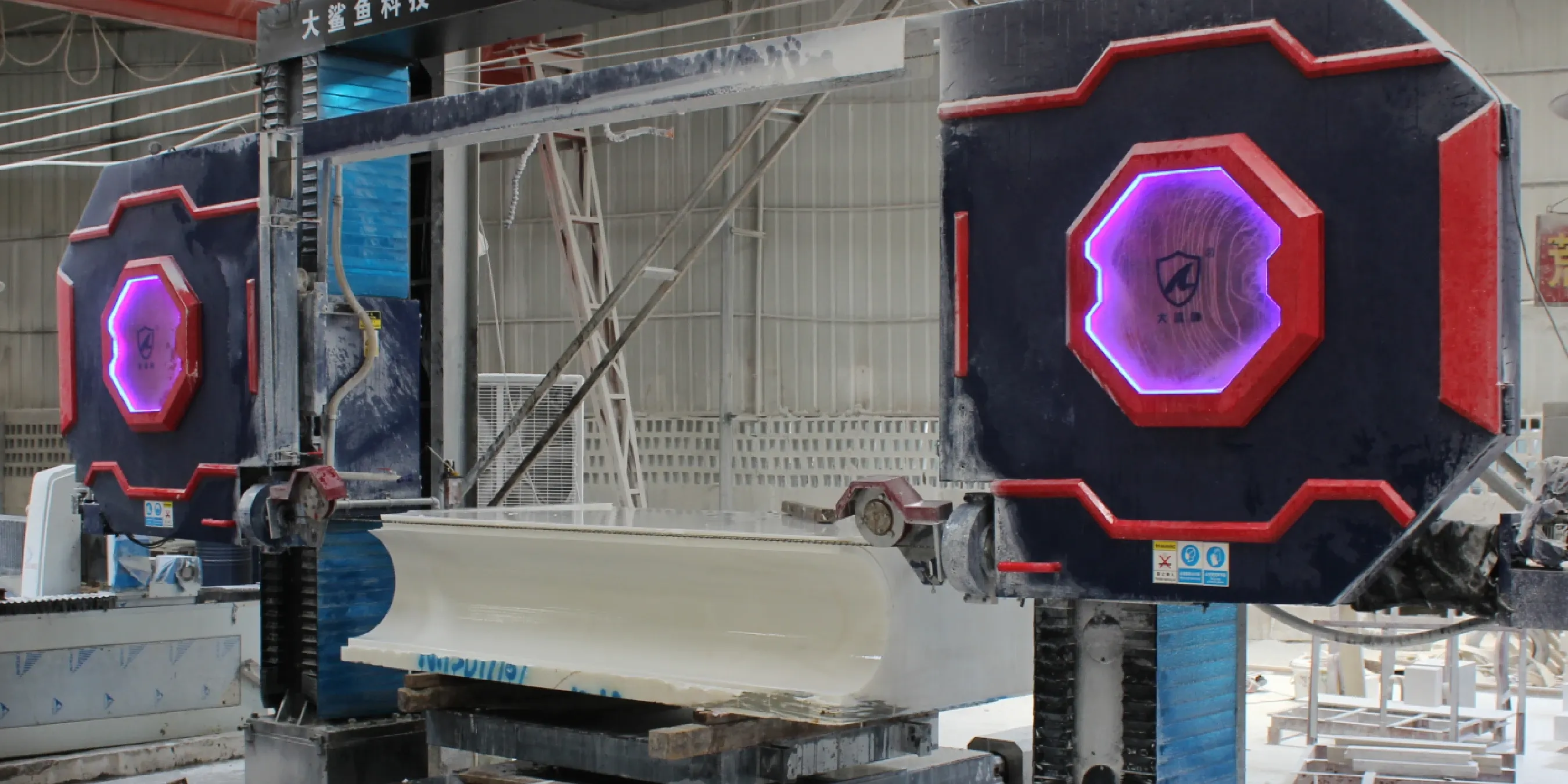

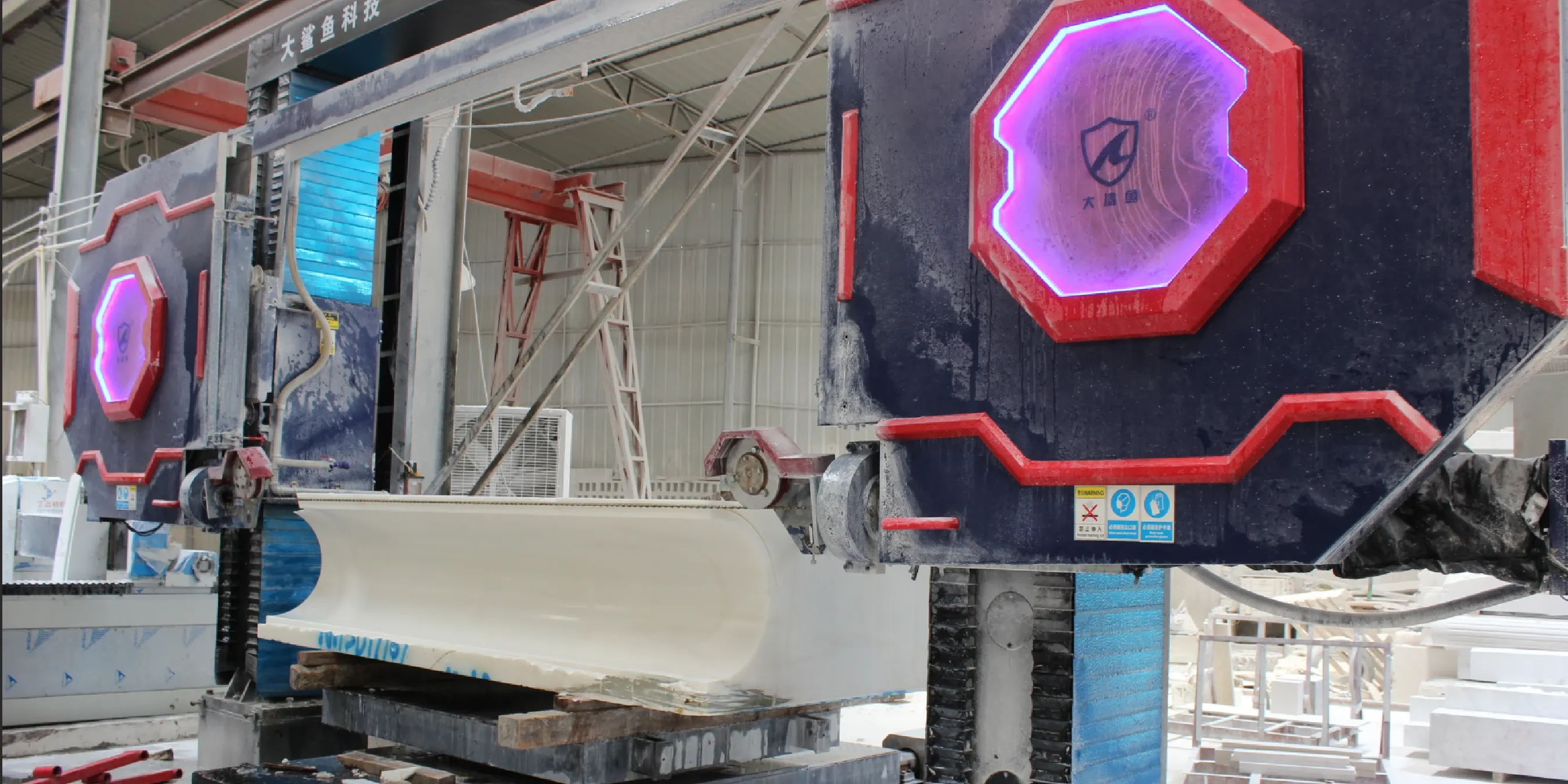

Marble curved panel and column wrap cutting case study using a CNC wire saw machine, showing precise profile cutting for architectural curved stone surfaces.

Case Snapshot

Material

Marble

Processing Method

CNC wire saw cutting

Typical Application

Curved marble panels and column wraps for architectural façades and interior stone features

Applicable Markets

Architectural stone fabrication, interior/exterior curved surfaces, stone façade projects

Processing Focus

Accurate arc, profile continuity, and edge condition on curved marble components

Associated Product

Dinosaw CNC wire saw machine

Marble Curved Panels and Column Wraps in Architectural Stonework

Curved marble panels and column wraps are common in architectural façades, atriums, lobbies, and interior feature walls.

Unlike straight slabs, curved components require precise control of contour geometry across multiple axes, so that surfaces align smoothly when assembled on building structures.

In modern fabrication workflows for high-end interiors and architectural stone façades, curved marble elements must not only follow design geometry but also maintain surface integrity and edge quality to minimize finishing effort on site.

Practical Challenges in Cutting Marble Curved Panels

Curved cutting of marble panels presents distinct workshop challenges:

Direction changes: Maintaining consistent curvature through multiple arc transitions

Profile continuity: Ensuring adjacent pieces align when joined

Surface integrity: Avoiding chips and micro-fractures along curved edges

Reproducibility: Producing multiple identical curved elements without dimensional drift

Standard saw blade cutting struggles with these challenges because it handles curves only by incremental positioning, which increases handling time and introduces variation.

Workshop Insights from Marble Curved Cutting Operations

What makes marble curved panel cutting demanding in daily production?

Operators often say the real challenge isn’t the curve itself — it’s keeping that curve consistent across every piece.

A single curved panel can be hand-adjusted, but once you need ten or twenty, even small deviations become visible when installed together.

Marble’s crystalline structure also makes it prone to edge breakouts if feed motion isn’t smooth.

Why is a CNC wire saw machine chosen for this task?

A CNC wire saw machine provides a continuous cutting action that naturally adapts to curved paths.

Instead of cutting straight lines only, the wire follows the programmed contour, allowing smooth transitions through arcs of varying radius.

This reduces vibration and localized stress on the marble, which helps preserve edge quality on curves.

What do operators focus on most during the cutting process?

Operators focus on wire tension and feed behavior throughout the cut.

Because the path constantly changes direction, stable motion and support are critical to prevent chatter or wobble that can produce surface irregularities.

They also monitor how the wire enters and exits the arc, adjusting support if necessary to maintain clean edges.

How is acceptable quality judged on the workshop floor?

Honest workshop evaluation is simple:

Pieces are arranged in dry assembly to check profile continuity.

Curves must align smoothly without visible kinks, and edge surfaces should be free of noticeable chips or roughness.

If adjacent panels fit seamlessly and minimize site finishing, the cut is considered acceptable.

How the Marble Curved Cutting Process Was Handled

Marble slabs designated for curved elements were positioned and securely supported to prevent movement during cutting.

The CNC wire saw machine was programmed with the required arc geometry and feed parameters.

Cutting was performed with controlled wire feed and tension, guiding the wire steadily through the entire curved path.

After cutting, components were visually checked and template-verified before entering polishing and finishing.

Observed Results in Marble Curved Panel Processing

Finished curved marble panels and column wraps showed smooth, consistent curvature across multiple pieces.

Edge quality remained intact through all transitions, with minimal chipping.

Dry assembly checks confirmed profile continuity, lowering finishing effort on site.

The cutting approach fit naturally into existing fabrication workflows for architectural stone components.

Who This Case Is Relevant For

If you are producing marble curved panels or column wraps for architectural or interior applications,

if accurate curvature and edge quality affect installation outcomes,

if multiple pieces must align smoothly without onsite rework,

this case reflects a practical curved cutting scenario commonly seen in stone fabrication workshops.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский