Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

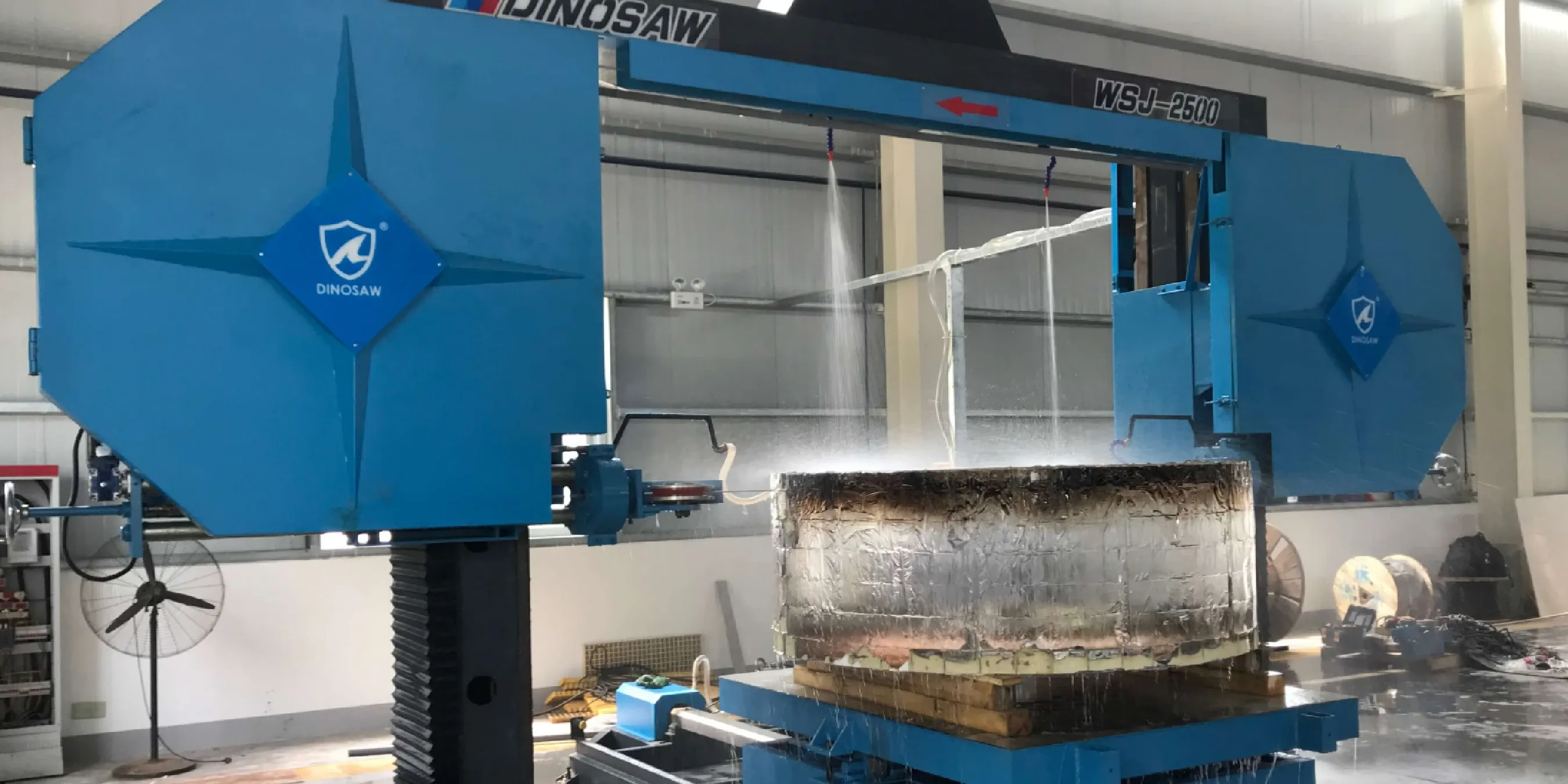

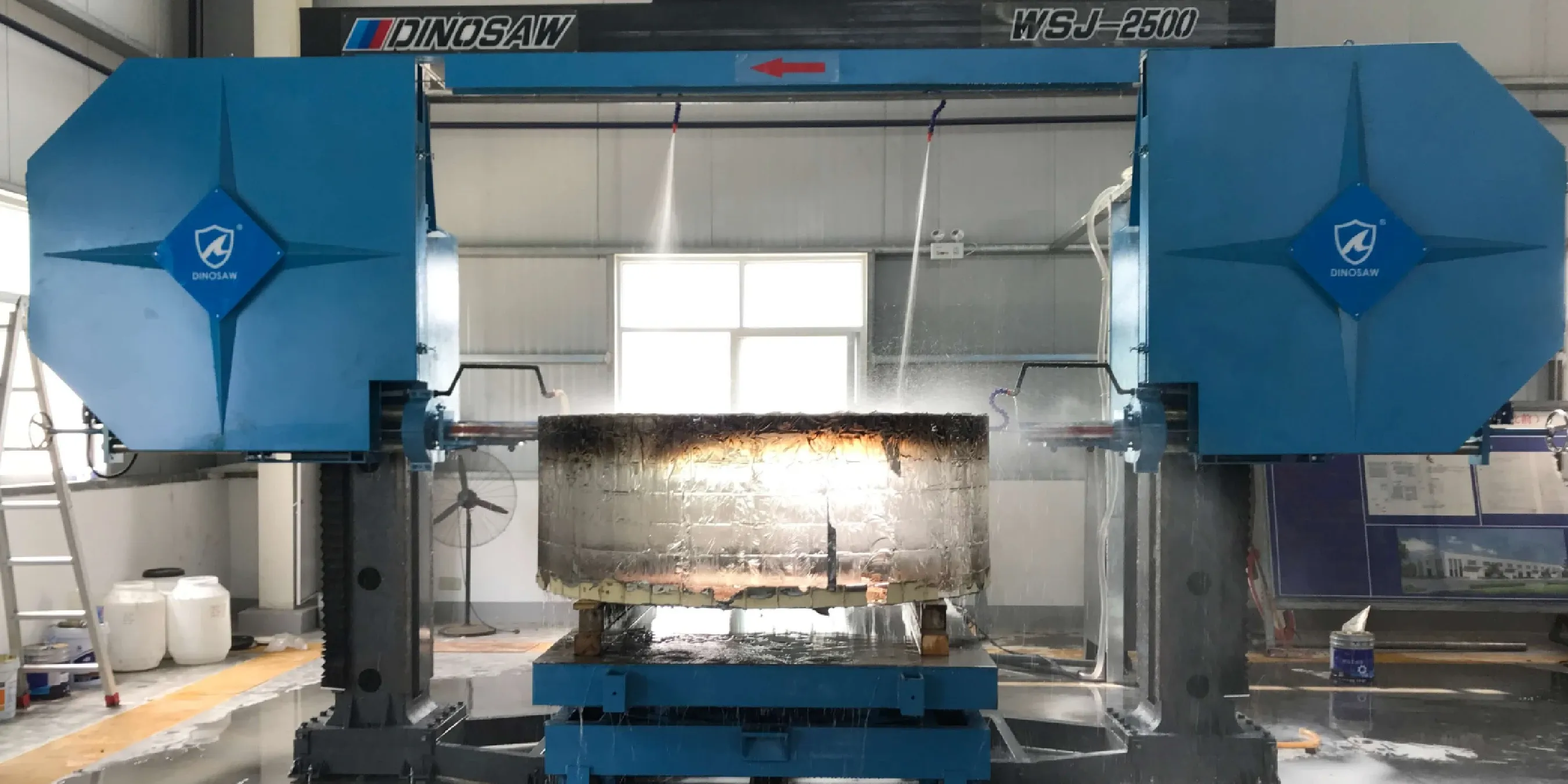

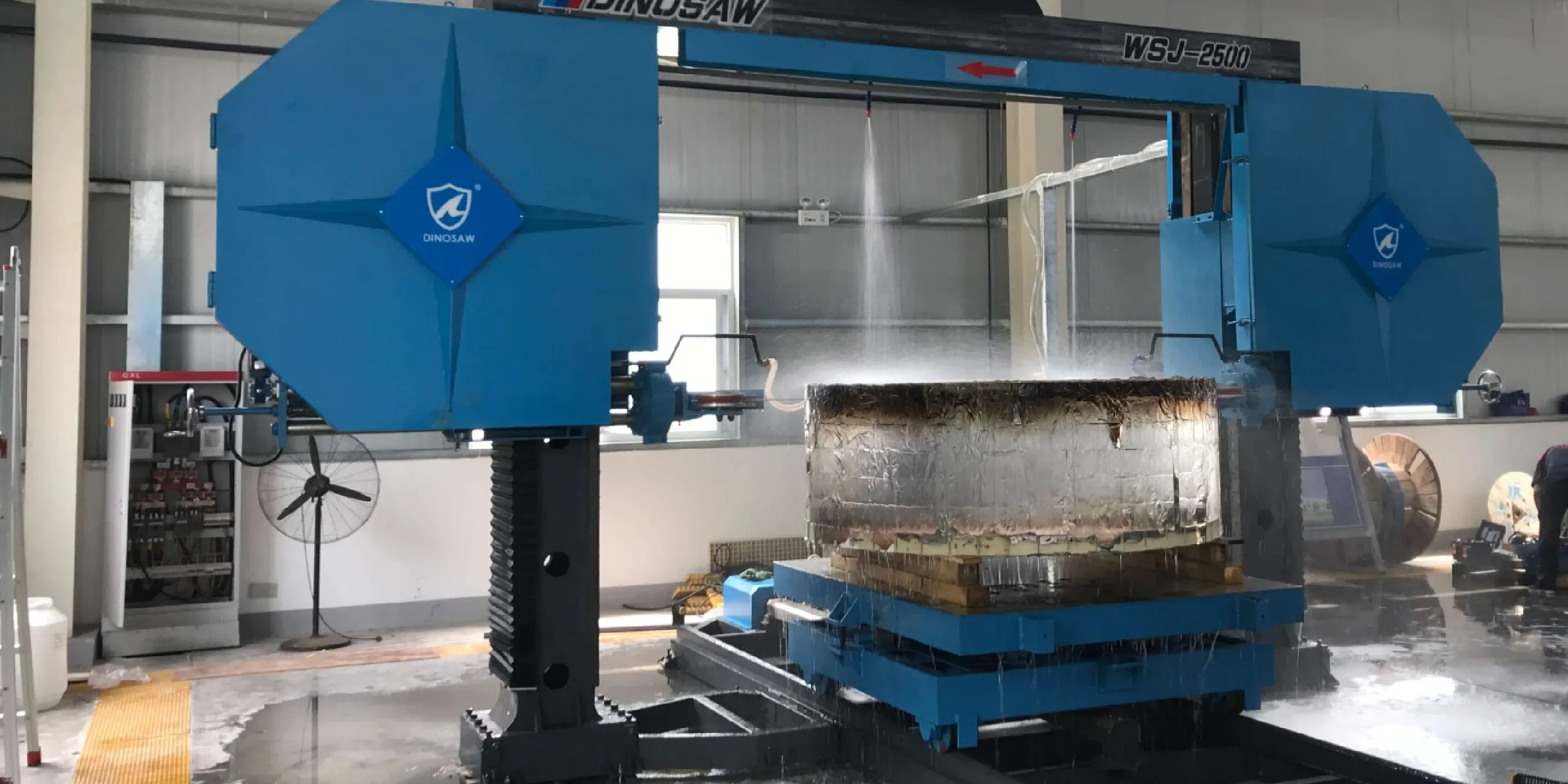

Quartz glass ingot cutting case study using a CNC wire saw machine, focusing on precise slicing of large cylindrical quartz blanks with minimal surface damage.

Case Snapshot

Material

Quartz glass (fused quartz)

Workpiece Form

Cylindrical quartz glass ingot / round blank

Processing Method

CNC wire saw cutting

Typical Application

Quartz glass ingot slicing for downstream machining, optical, semiconductor, and industrial components

Processing Focus

Crack prevention, surface integrity, dimensional stability

Associated Product

Dinosaw CNC Diamond Wire Saw Machine

Quartz Glass Ingots in Industrial Manufacturing

Quartz glass ingots are widely used as base material for high-precision industrial components, including optical parts, semiconductor consumables, and thermal-resistant elements.

Unlike natural stone, fused quartz is hard, brittle, and extremely sensitive to cutting stress, making the initial ingot slicing stage critical for overall yield.

Large-diameter cylindrical ingots require stable, low-vibration cutting to avoid internal micro-cracks that may not be visible immediately but cause failures in later processing.

Cutting Challenges with Quartz Glass Ingots

From the workshop perspective, quartz glass ingot cutting presents several well-known challenges:

High brittleness: Even small mechanical shocks can initiate cracks

Internal stress sensitivity: Uneven cutting forces can lead to delayed fractures

Surface integrity requirements: Excessive chipping increases grinding workload

Large cross-section size: Thick ingots demand stable long-duration cutting

Traditional blade cutting often introduces localized stress at the cutting edge, which is difficult to control on large cylindrical quartz blanks.

Workshop Perspective: Why Wire Saw Cutting Is Chosen

Why is quartz glass not cut like stone blocks?

Operators point out that quartz glass behaves very differently from stone.

It does not tolerate intermittent contact or aggressive feed.

Any sudden load change can propagate cracks through the ingot, sometimes only becoming visible after further machining.

What role does the CNC wire saw machine play here?

A CNC wire saw machine applies continuous, uniform cutting force around the entire cutting path.

The diamond wire gradually removes material instead of forcing a rigid blade through the ingot, significantly reducing stress concentration inside the quartz glass.

What do operators monitor during cutting?

Operators closely monitor wire tension stability, feed rate, and coolant flow.

Cutting speed is deliberately controlled to maintain smooth material removal and consistent thermal conditions, especially on large-diameter ingots where cutting time is long.

How is cutting quality evaluated?

Quality is evaluated by checking:

Absence of visible cracks or edge chipping

Flatness and dimensional consistency of sliced sections

Surface condition suitable for downstream grinding or polishing

If the sliced blanks remain structurally stable after cutting and handling, the process is considered successful.

How the Quartz Glass Ingot Cutting Was Performed

The quartz glass ingot was securely positioned on the machine table with proper support to avoid vibration.

The CNC wire saw machine was programmed for controlled feed and stable wire tension suitable for fused quartz.

Cutting proceeded in a continuous motion, allowing the wire to pass smoothly through the cylindrical ingot.

Cooling water was applied consistently to manage temperature and remove cutting debris.

Results Observed in Production

The sliced quartz glass blanks showed clean separation with minimal edge damage.

No visible cracking was observed during or after cutting.

Dimensional accuracy met downstream processing requirements, reducing rework and scrap risk.

The cutting process proved stable for large-size quartz ingots in continuous operation.

Who This Case Is Relevant For

This case is relevant if you are working with:

Quartz glass or fused quartz ingots

Large-diameter cylindrical blanks

Brittle materials requiring low-stress cutting

High-value components where yield and integrity matter

If your priority is stable slicing without hidden damage, this cutting approach reflects a practical solution used in real production environments.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский